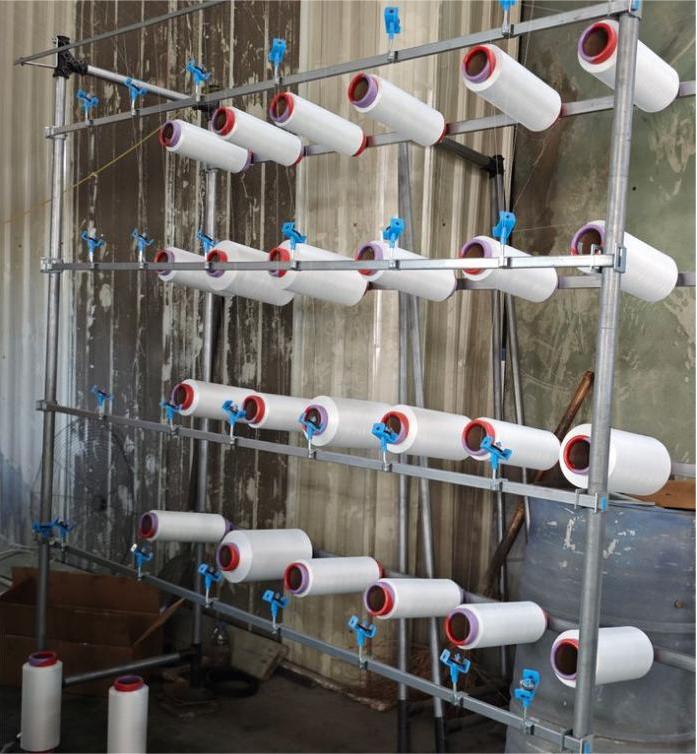

I.Ukufakwa kwe-Yarn Stand (Uhlelo lwe-Creel & Yarn Carrier)

1. Ukuma & Ukumisa

• Beka itende lokuluka intambo ngamamitha angu-0.8–1.2 ukusuka emshinini wokuluka oyindilinga(https://www.eastinoknittingmachine.com/products/), ukuqinisekisa okungenani u-600 mm wemvume yomqhubi.

• Sebenzisa izinga lokunemba ukuze uqinisekise ukuthi izinduku ezime mpo zinokuchezuka kwe-perpendicularity ≤ 0.5 mm/m. Lungisa izinyawo zokusekela noma izihlukanisi zokudlidliza uma kudingeka.

• Sebenzisa i-torque wrench ukuze uqinise amabhawodi esisekelo ngokudayagonali ukuvimbela ukungqubuzana kozimele.

2. Ukulandelana Komhlangano (Isibonelo Sokusetha Okusekelwe Kulungelo Lobunikazi)

1. Faka induku ye-spool yentambo (12) ohlakeni lokusekela (11), bese uvikela ngezinduku zokuxhuma (4).

2. Gcoba izinti ezingenhla (3) indawo egobile ibheke phezulu. Izingwegwe zentambo yesikhala (31) cishe ngokuphindwe ka-1.2 kwenani lama-spools, asakazwa ngokulinganayo.

3. Faka ugongolo lwentambo yomhlahlandlela (21). Setha iziqondiso zezintambo (211) ngesikhala esifana nenani leziphakeli zezintambo emshinini wokunitha.

4. Zungezisa i-disc yentambo (2114) ukuze i-groove yentambo (21141) iqondane nomlomo wokuphakelayo. Qinisekisa ukuthi i-shaft ejikelezayo (2113) ijikeleza ngokukhululeka.

3. Ukulinganisa Okusheshayo

• Sebenzisa indlela yokuphambana kwezintambo: nweba umugqa onqamulayo ukusuka esikhungweni somshini wokuluka uye emagumbini amane omugqa wentambo. Ukuchezuka kwebanga elingu-≤ 2 mm kuyamukeleka.

•Nyakazisa kancane isitendi sentambo ukuze uhlole ukunyakaza okungafuneki—uma izinzile, isilungele ukulayishwa intambo.

I.Ukusethwa Kwendlela Yentambo (Ukucushwa Nokuqondanisa Kokudla)

1. Isakhiwo Esijwayelekile Sokucushwa

I-Yarn ihamba kanje:

Ikhoni yentambo → I-Tensioner → Ihuku lentambo / iso le-ceramic → Isitholi sokunqamuka kwentambo → Umhlahlandlela wentambo → Isiphakeli sentamboumshini wokuluka oyindilinga.

• Intambo kufanele idlule nge-engeli yokugoqa engu-30–45° ukuze kugwenywe ukulimala kwengcindezi.

• Ama-tension esigabeni esifanayo kufanele alingane, phakathi kuka-±2 mm.

2. Ukulungiswa Kwengcindezi Ngohlobo Lwentambo

• Ukotini/i-Polyester: 3–5 cN; igebe lepuleti lokushuba ~ 2 mm.

• I-Spandex (Elastane): 0.5-1.5 cN; hlanganisa izinduku zokunqanda ukugxambukela.

• Intambo ye-filament: 2-4 cN; sebenzisa izingwegwe zentambo ye-ceramic ukuze unciphise i-static.

3. Izithuthukisi Eziqhutshwa Ngamalungelo Obunikazi (CN208038689U)

• Izinti zokumisa ezingenhla nezingezansi (1211/1213) zakha i-engeli e-acute engu-10–15° ngezinduku ezime mpo, zidonsela isikhungo sekhoni yentambo ngaphakathi ukuze kuvuleke kalula.

• Yondla intambo ngayinye ngehuku lentambo (31) ngaphambi kokungena kumhlahlandlela wentambo ukuze unikeze ukuhlukaniswa okuphindwe kabili—lokhu kunciphisa ubungozi bokuhlangana ngama-30%.

III. Uhlu Lokuhlola Lokulungisa Amaphutha Esayithi

| Into | Okujwayelekile Okuqondisiwe | Amathuluzi Ayadingeka

| Intambo ime mpo | ≤ 0.5 mm/m | Izinga lokunemba

| Ukuqondanisa komhlahlandlela wentambo | ≤ 0.2 mm ukuchezuka | I-Feeler gauge

| Ukungaguquguquki kwengcindezi | ±0.5 cN phakathi kweziphakeli | Imitha ye-tension yedijithali

| Ukugijima okomile (5 imiz) | Akukho ukugqashuka kwentambo / ukudlidliza| Ukuhlola okubonakalayo

IV. Izinkinga Ezivamile Nokulungiswa Okusheshayo

| Inkinga | Kungenzeka | Isixazululo

| Amakhefu avamile | Ihuku lentambo elimele noma ukungezwani okuphezulu | Faka esikhundleni se-ceramics, unciphise ukungezwani

| Ukufakwa kwentambo | Ikhoni itshekile ingumqansa kakhulu noma iqondisa kude kakhulu | Nciphisa i-engeli, finyeza i-guide-to-feeder pat

| Ukungafani kokuqina | Ubude bekhoni elingalingani | Qondanisa kabusha ukuphakama kwe-cone stand

Isiphetho

Ngokulandela lo mhlahlandlela wokusetha, ungakwazi ukuqedela ukufakwa kwesitendi sentambo kanye nokucushwa kwendlela yentambo ngaphansi kwemizuzu engama-30—ukunika amandlaumshini wokuluka oyindilingaukusebenza kahle, ngempumelelo, kanye nesikhathi esincishisiwe sokuphumula. Ukuphakelwa kahle kwentambo kuyisisekelo sokuphuma kwendwangu yekhwalithi ephezulu kanye nokusebenza kahle komshini wokunitha emisebenzini yesimanje yendwangu.

Isikhathi sokuthumela: Jul-24-2025