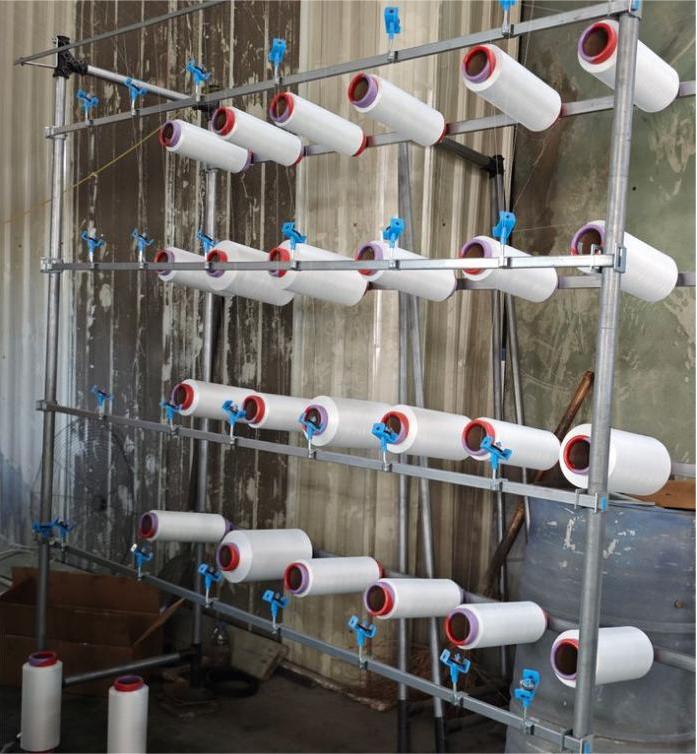

I.UFakelo lweSimemo soMsonto (iCreel kunye neNkqubo yokuThuthwa kweMisonto)

1. Ukuma kunye nokuQinisekisa

• Beka isitendi somsonto kwiimitha ezi-0.8–1.2 ukusuka kumatshini wokunitha ojikelezayo(https://www.eastinoknittingmachine.com/products/), eqinisekisa ubuncinci be-600 mm yokukhutshwa komsebenzisi.

• Sebenzisa inqanaba elichanekileyo ukuqinisekisa ukuba iintonga ezithe nkqo zinokuphambuka kwe-perpendicularity ≤ 0.5 mm/m. Lungisa iinyawo zenkxaso okanye i-vibration isolator ukuba kuyimfuneko.

• Sebenzisa i-torque wrench ukuqinisa ngokwediagonal iibholithi zesiseko ukuthintela ukujika kwefreyim.

2. Ulandelelwano lweNdibano (Umzekelo wokuSekwa okuSekwe kwiPatent)

1. Faka umsonto we-spool umsonto (12) kwisakhelo sokuxhasa (11), emva koko ukhusele ngeentonga zokudibanisa (4).

2. Faka imisonto ephezulu (3) indawo egobileyo ijonge phezulu. Amakhonkco omsonto wesithuba (31) malunga ne-1.2x inani lee-spools, ezisasazwe ngokulinganayo.

3. Faka umqadi womsonto wesikhokelo (21). Cwangcisa izikhokelo zemisonto (211) kunye nezithuba ezihambelana nenani lezinto ezitya intambo kumatshini wokunitha.

4. Jikelezisa idiskhi yomsonto (2114) ukuze i-groove yomsonto (21141) ihambelane nomlomo wesondlo. Qinisekisa ishaft ejikelezayo (2113) ijikelezisa ngokukhululekileyo.

3. Ukulinganisa ngokukhawuleza

• Sebenzisa indlela yokunqumla imisonto: yolula umgca onqamlezileyo ukusuka kumbindi womatshini wokunitha ukuya kwiikona ezine zesitendi somsonto. Ukuphambuka komgama we-≤ 2 mm kwamkelekile.

• Hlikihla kancinane isitendi somsonto ukujonga intshukumo engafunekiyo—ukuba izinzile, ilungele ukulayishwa.

I.Umiselo lweNdlela yoMsonto (UkuTyala kunye noLungelelwaniso lokutyisa)

1. UYilo loMsonto oMgangatho

Umsonto uhamba ngolu hlobo lulandelayo:

Ikhowuni yomsonto → Isithinteli → Ihuku yomsonto / iliso leceramic → Isichopheli soqhawulo-msonto → Isikhokelo somsonto → Isiphakeli somsonto kwiumatshini wokunitha ojikelezayo.

• Umsonto kufuneka ugqithe nge-engile yokusonga eyi-30–45° ukuthintela umonakalo woxinzelelo.

• Ii-tensioners ezikwinqanaba elinye kufuneka zilingane enye kwenye, ngaphakathi kwe-±2 mm.

2. Uhlengahlengiso lweTension ngoNxibelelo lweMsonto

• Umqhaphu/iPolyester: 3–5 cN; umsantsa kwipleyiti yoxinzelelo ~ 2 mm.

• I-Spandex (Elastane): 0.5-1.5 cN; zibandakanya iintonga ezichasene nokungena.

• Umsonto weFilament: 2–4 cN; sebenzisa iigwegwe zomsonto weceramic ukunciphisa i-static.

3. Izincedisi eziqhutywa yiPatent (CN208038689U)

• Iirodi zokumisela eziphezulu nezisezantsi (1211/1213) zenza i-engile eyi-10–15° ebukhali eneentonga ezithe nkqo, itsalela umsonto wekhowuni embindini womxhuzulane ngaphakathi ukuze uphumle kamnandi.

• Yondla umsonto ngamnye nge hook yomsonto (31) phambi kokuba ungene kwisikhokelo somsonto ukunika ukwahlula kabini—oku kunciphisa umngcipheko wokubhijela ngaphezulu kwama-30%.

III. Uluhlu lokuHlola olukwiSite

| Into | Umgangatho ekujoliswe kuwo | Izixhobo ezifunekayo

| Umsonto ume nkqo | ≤ 0.5 mm/m | Inqanaba lokuchaneka

| Ulungelelwaniso lwesikhokelo somsonto | ≤ 0.2 mm ukutenxa | Igeyiji yokuziva

| Ukuhambelana koxinzelelo | ±0.5 cN phakathi kwabaxhasi | imitha yoxinzelelo lwedijithali

| Ukubaleka okomileyo (imizuzu emi-5) | Akukho kuqhawuka komsonto / ukungcangcazela| Ukuhlolwa okubonakalayo

IV. Imiba eqhelekileyo kunye noLungiso oluKhawulezayo

| Ingxaki | Mhlawumbi Unobangela | Isisombululo

| Iikhefu rhoqo | Ihuku yomsonto eyonakeleyo okanye uxinzelelo oluphezulu | Faka iiseramics endaweni, ukunciphisa uxinzelelo

| Ukufakwa komsonto | Icone ithambeka kakhulu okanye ikhokela kude kakhulu | Nciphisa i-engile, mfutshane isikhokelo-kwi-feeder pat

| Ukungahambelani koxinzelelo | Ukuphakama kwekowuni engalinganiyo | Lungelelanisa kwakhona ukuphakama kwekhowuni

Ukuqukumbela

Ngokulandela esi sikhokelo sokuseta, ungagqibezela ufakelo lokumisa umsonto kunye noqwalaselo lwendlela yomsonto ngaphantsi kwemizuzu engama-30-ukwenza ukubaumatshini wokunitha ojikelezayoukusebenza kakuhle, ngokufanelekileyo, kunye nexesha elincitshisiweyo lokuphumla. Ukutya okufanelekileyo kwelaphu kusisiseko semveliso yelaphu ekumgangatho ophezulu kunye nokusebenza komatshini wokunitha ngokufanelekileyo kwimisebenzi yelaphu yanamhlanje.

Ixesha lokuposa: Jul-24-2025