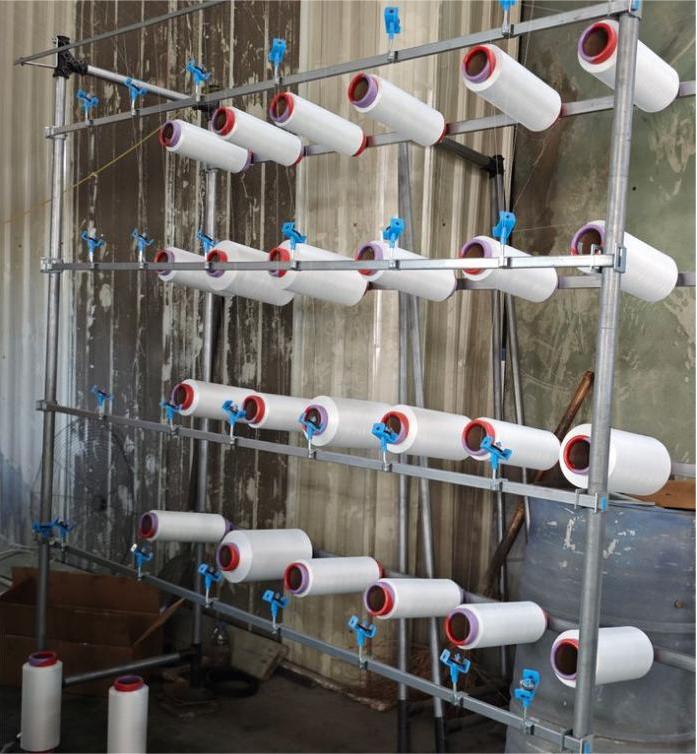

I.Yarn Stand Installation (Creel & Yarn Carrier System)

1. Positioning & Anchoring

• Isa chigadziko cheshinda 0.8–1.2 metres kubva pamuchina wedenderedzwa wekuruka(https://www.eastinoknittingmachine.com/products/), kuve nechokwadi chekuti 600 mm yemvumo yevashandisi.

• Shandisa chiyero chakarurama kuti uone kuti tsvimbo dzakamira dzine perpendicularity deviation ≤ 0.5 mm/m. Gadzirisa tsoka dzekutsigira kana vibration isolator kana zvichidikanwa.

• Shandisa chipanera che torque kuti usimbise mabhaudhi egadziko kuitira kudzivirira kuputika kwefuremu.

2. Gungano Sequence (Patent-Yakavakirwa Setup Muenzaniso)

1. Isai shinda spool danda (12) murutsigiro furemu (11), uye chengetedza nekoneki rods (4).

2. Isa tambo dzepamusoro (3) nzvimbo yakakombama yakatarisa kumusoro. Space yarn hoko (31) ingangoita 1.2x nhamba yespools, yakagoverwa zvakaenzana.

3. Isai danda regwara (21). Seta madhairekitori eshinda (211) nekupatsanura kunoenderana nenhamba yezvipfuyo zveshinda pamushini wekuruka.

4. Tenderedza dhisiki reshinda (2114) kuitira kuti shinda yeshinda (21141) ienderane nemuromo wekudyisa. Ita shuwa kuti shaft inotenderera (2113) inotenderera zvakasununguka.

3. Fast Calibration

• Shandisa tambo-muchinjikwa nzira: tambanudza muchinjiko kubva pakati pemuchina wekuruka kusvika kumakona mana echigadziko cheshinda. Kutsauka kure ≤ 2 mm kunogamuchirwa.

• Zunza chigadziko cheshinda zvishoma kuti utarise kana shinda isingade—kana yakasimba, yagadzirira kukwirisa shinda.

I.Yarn Path Setup (Kurukwa uye Kudyisa Alignment)

1. Standard Threading Layout

Yarn inofamba sezvinotevera:

Koni yeshinda → Tensioner → Chiredzo cheshinda / ziso receramic → Mucherechedzo weshinda yeshinda → Gwaro reshinda → Feeder yeshinda padenderedzwa knitting muchina.

• Shinda inofanira kupfuura nekona yekupeta ye30–45 ° kudzivirira kukanganisa kunetseka.

• Mabatirwo ari pachikamu chimwe chete anofanira kuenzana, mukati me ±2 mm.

2. Kugadziriswa kweTension neYarn Type

• Cotton / Polyester: 3-5 cN; tension plate gap ~ 2 mm.

• Spandex (Elastane): 0.5-1.5 cN; sanganisira anti-entangling tsvimbo.

• Filament yarn: 2-4 cN; shandisa ceramic yarn hooks kuderedza static.

3. Patent-Driven Enhancements (CN208038689U)

• Matanda ekuseta ekumusoro neazasi (1211/1213) anoumba 10–15° acute angle ine matinji akatwasuka, achikwevera shinda koni yepakati yegiravhiti mukati kuti isununguke zvakanaka.

• Dyisa shinda imwe neimwe kuburikidza nechirauro cheshinda (31) usati wapinda mugwara reshinda kuti upe kupatsanurwa kwakapetwa kaviri-izvi zvinoderedza njodzi yekukochekera neinopfuura 30%.

III. Pa-Site Debugging Checklist

| Chinhu | Target Standard | Zvishandiso Zvinodiwa

| Yarn stand verticality | ≤ 0.5 mm/m | Precision level

| Yarn guide alignment | ≤ 0.2 mm kutsauka | Feeler gauge

| Tension consistency | ±0.5 cN pakati pevanodyisa | Digital tension mita

| Dry run (5 mins) | Hapana shinda yekutyoka / vibration| Kuongorora kwekuona

IV. Zvakajairwa Nyaya & Kugadzirisa Kurumidza

| Dambudziko | Zvichida Chikonzero | Solution

| Kakawanda kuzorora | Yakakuvadzwa yeshinda hoko kana yakakwirira tension | Tsiva ceramics, kuderedza kushushikana

| Yarn entanglement | Koni inorereka yakanyanyisa kana kutungamira kureba | Deredza kona, pfupisa gwara-ku-feeder pat

| Tension mismatch | Uneven cone urefu | Re-align cone stand urefu

Mhedziso

Nekutevera iyi yekumisikidza gwara, unogona kupedzisa kuisirwa shinda yekumira uye shinda nzira yekumisikidza mukati memaminitsi makumi matatu-kugonesa yako.denderedzwa knitting muchinakuti imhanye zvakanaka, zvinobudirira, uye nenguva yakadzikira. Kudyisa shinda kwakaringana ndiyo hwaro hwekubuda kwejira remhando yepamusoro uye kuita kwakaringana kwemuchina wekuruka mumabasa emazuva ano emachira.

Nguva yekutumira: Jul-24-2025