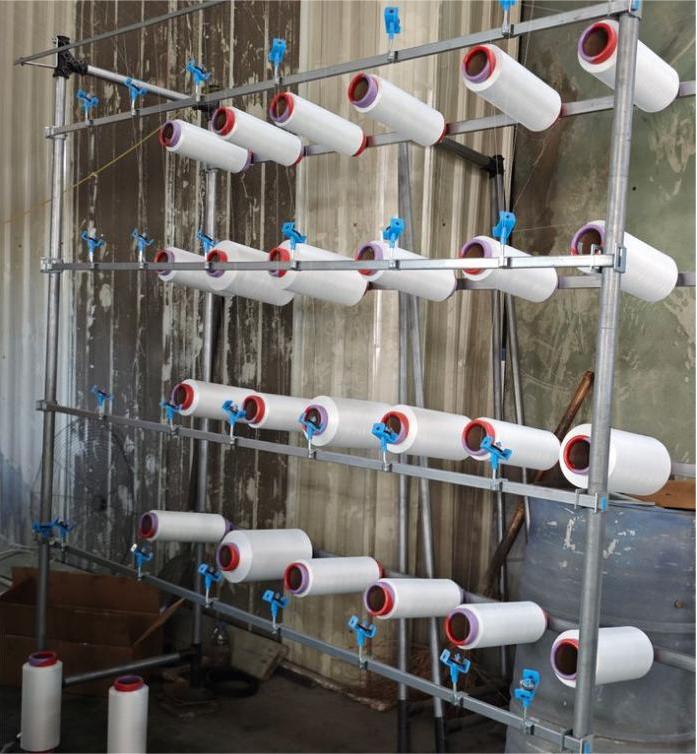

Kuv.Yarn Stand Installation (Creel & Yarn Carrier System)

1. Txoj hauj lwm & Anchoring

• Muab cov xov paj sawv ntsug 0.8–1.2 meters ntawm lub voj voog knitting tshuab(https://www.eastinoknittingmachine.com/products/), kom ntseeg tau yam tsawg kawg 600 hli ntawm tus neeg teb xov tooj clearance.

• Siv cov qib precision kom ntseeg tau tias cov pas nrig ntsug muaj qhov sib txawv perpendicularity ≤ 0.5 mm / m. Kho cov kev txhawb nqa ko taw lossis kev vibration isolators yog tias xav tau.

• Siv ib lub torque wrench kom diagonally nruj lub hauv paus bolts los tiv thaiv thav duab warping.

2. Kev Sib Txuas Ua Ke (Patent-Based Setup Example)

1. Ntxig cov xov paj spool beam (12) rau hauv cov khoom txhawb nqa (11), ces ruaj ntseg nrog cov hlua txuas (4).

2. Mount cov yarn sab saud (3) nrog lub ntsej muag nkhaus tig upward. Chaw yarn hooks (31) kwv yees li 1.2x tus naj npawb ntawm spools, sib npaug.

3. Txhim kho cov lus qhia xov paj (21). Teem cov xov paj qhia (211) nrog qhov sib txawv uas sib npaug ntawm cov xov paj feeders ntawm lub tshuab knitting.

4. Tig lub xov paj disc (2114) kom cov xov paj zawj (21141) sib haum nrog lub qhov ncauj feeder. Xyuas kom lub rotating ncej (2113) tig dawb do.

3. Ceev Calibration

• Siv txoj hlua hla txoj hlua: ncab ib txoj kab hla ntawm lub tshuab knitting mus rau plaub fab ntawm cov xov paj. Qhov kev ncua deb ntawm qhov sib txawv ntawm ≤ 2 mm tau txais.

• Maj mam co lub xov tooj sawv ntsug los xyuas seb qhov tsis xav tau txav mus los—yog tias ruaj khov, nws npaj txhij rau kev thauj khoom xov paj.

Kuv.Kev teeb tsa xov paj (Threading & Feeding Alignment)

1. Txheem Threading Layout

Cov xov paj mus raws li hauv qab no:

Lub khob hliav qab → Tensioner → Xov xov nuv / ceramic qhov muag → Xov paj tawg ntes → Xov paj qhia → Xov paj feeder ntawm lubncig knitting tshuab.

• Cov xov paj yuav tsum hla nrog lub kaum sab xis ntawm 30–45 ° kom tsis txhob muaj kev ntxhov siab.

• Tensioners ntawm tib theem yuav tsum nyob rau hauv ib leeg, nyob rau hauv ± 2 hli.

2. Kev hloov kho nruj los ntawm cov xov paj

• Paj Rwb/Polyester: 3–5 cN; nro phaj qhov sib txawv ~ 2 hli.

• Spandex (Elastane): 0.5–1.5 cN; suav nrog anti-entangling rods.

• Filament yarn: 2–4 cN; siv cov xov paj ceramic hooks los txo qhov zoo li qub.

3. Patent-Driven Enhancements (CN208038689U)

• Sab saum toj thiab qis qhov chaw rods (1211/1213) tsim 10-15 ° mob lub kaum sab xis nrog rau txoj kab ntsug, rub cov xov paj lub hauv paus ntawm lub ntiajteb txawj nqus sab hauv kom smoother unwinding.

• Pub txhua cov xov paj los ntawm ib lub xov tooj sib txuas (31) ua ntej nkag mus rau hauv phau ntawv qhia xov paj kom muab ob npaug rau kev sib cais—qhov no txo qis kev pheej hmoo ntawm tangling ntau dua 30%.

III. On-Site Debugging Checklist

| Yam khoom | Hom phiaj | Cov cuab yeej xav tau

| Xov paj sawv ntsug ntsug | ≤ 0.5 hli / m | Qib Precision

| Xov paj qhia kev sib raug zoo | ≤ 0.2 hli sib txawv | Lub siab ntsuas

| Nruas sib xws | ± 0.5 cN ntawm feeders | Digital Tension Meter

| Qhuav khiav (5 mins) | Tsis muaj xov paj tawg / vibration| Kev tshuaj xyuas qhov muag

IV. Cov Teeb Meem Ntau & Kev Kho Ceev

| Teeb meem | Yuav Ua Li Cas | Kev daws

| Nquag so | Kev puas tsuaj yarn nuv lossis siab nro | Hloov cov ceramics, txo qhov nro

| Xov xwm entanglement | Lub khob tilt dhau los yog coj deb dhau | Txo lub kaum sab xis, luv luv qhia-rau-feeder pat

| Nyuaj tsis sib haum | Lub khob hliav qab qhov siab | Re-align cone sawv qhov siab

Xaus

Los ntawm kev ua raws li phau ntawv qhia kev teeb tsa no, koj tuaj yeem ua tiav cov xov tooj sawv ntsug thiab kev teeb tsa cov xov paj hauv qis dua 30 feeb-ua rau kojncig knitting tshuabkom khiav tau yooj yim, ua tau zoo, thiab nrog kev txo qis qis. Kev noj cov xov paj zoo yog lub hauv paus rau cov ntaub ntawv zoo tshaj plaws thiab kev ua haujlwm zoo knitting tshuab hauv kev ua haujlwm niaj hnub textile.

Post lub sij hawm: Lub Xya hli ntuj-24-2025