5TH:Maintenance of motor and circuit system

The motor and circuit system, which is the power source of the knitting machine, must be strictly inspected regularly to avoid unnecessary breakdowns.The following are the key points of the work:

1、Check the machine for leakage

2、Check whether the fuse and the carbon brush for the motor are damaged(V.S. Motors and inverter motors without carbon brush)

3、Check the switch for malfunction

4、Check the wiring for wear and disconnection

5、Check the motor, connect the line, clean the bearings (bearings) and add lubricating oil

6、Check the relevant gears, synchronous wheel and belt pulleys in the drive system, and check for abnormal noise, looseness or wear.

7、Take down system: Check the oil mass of gearbox once a month, and add with an oil gun.

Use 2# MOBILUX lubricating grease; or SHELL ALVANIL 2# lubricating grease; or WYNN multi-purpose lubricating grease. Or refer to the “Instruction Manual for Fabric Rolling down system”.

6TH:Adjustment, recording and input of speed

1、The running speed of the machine is set, memorized and controlled by the inverter

2、To make a setting, press A to advance one digit and V to retreat one digit,Press > to move one position to the right.After the setting is completed, press DATA to record, and the machine will run according to your instruction speed.

3、When the machine is running, please do not indiscriminately press the various keys of the inverter.

4、For the use and maintenance of the inverter, please read the “Inverter and Instruction Manual” in detail

7TH:Oil Nozzle

1、Mist type auto oiler

A、Connect the air outlet of the air compressor to the air inlet of the automatic fuel injector with a plastic tube, and add needle oil to the tank of the auto oiler.

B、Adjust the air compressor and oil supply, the oil mass should be larger when the machine is new, so as not to pollute the fabric.

C、Insert all sections of the oil tube firmly, and when you start the machine, you can see the oil flow in the tube, that is, it is normal.

D、Regularly remove the sewage from the air filter.

2、Electronic auto oiler

A、The operating voltage of the electronic auto oiler is AC 220±20V, 50MHZ.

B、^ Select the time key and press once to move up one frame.

C. >Oil hole moving key, press once to move one grid, divided into ABCD four groups.

3、SET/RLW Setting operation key, press this key when resetting, and press this key when setting is completed.

4、All setting keys are set to press this key at the same time

5、AU shortcut Press this key to quickly add oil.

8TH:Machine gate

1、One of the three gate of the machine is movable for fabric rolling, and the gate must be fastened before the machine runs.

2、The movable gate is equipped with a sensor that stops the gate immediately when it is opened.

9TH:Needle detector

1、The Needle detector will jump out immediately when the knitting needle breaks, and will quickly transmit it to the control system, and the machine will stop running within 0.5 seconds.

2、When Needle breaks, the Needle detector emits a flash of light.

3、After replacing the new needle, please press the needle breaker to reset it.

10TH:Yarn storage device

1、The yarn storage device plays an positive role in feeding yarn in the machine.

2、When a certain yarn breaks, the red light of the yarn storage device will flash and the machine will stop running quickly within 0.5 seconds.

3、There are separate and non-separable yarn storage devices. The separate yarn storage device has a clutch, which is driven upward by the upper pulley and downward by the lower pulley. When rewinding the yarn, pay attention to whether the clutch is engaged.

4、When lint is found to accumulate in the yarn storage device, it should be cleaned up in time.

11ST:Radar dust collector

1、The operating voltage of the radar dust collector is AC220V.

2、The radar dust collector will rotate with the machine in all directions to remove the lint when the machine is started, and it will also stop rotating when the machine stops.

3、The radar dust collector will not rotate when the button is pressed.

4、For radar dust collectors, the reversing box on the top of the central shaft is equipped with carbon brushes, and the dust in the reversing box should be cleaned by an electrician every quarter.

Notice:

The belt tension must be adjusted accordingly to the diameter of the yarn feed wheel each time.

12TH:Clearance Check

A、Use a feeler gauge to check the gap between the needle cylinder and the triangle of the lower circle. The gap range is between 0.2mm-0.30mm.

B、The gap between the needle cylinder and the triangle of the upper plate. The gap range is between 0.2mm-0.30mm.

Replacement of sinkers:

If the sinker needs to be replaced, it is preferred to turn the sinker manually to the notch position. Loosen the screws, remove the upper plate cutout, and only then replace the old sinker.

C、Replacement of needles:

The position between the needle latch and the detector, the position of the detector should be in the normal position and the knitting needle can pass through smoothly without stopping due to touching the detector.Needle selection and its installation should be very careful, to turn the machine manually to the mouth position, and then remove the faulty needle from the bottom and replace it with a new needle.

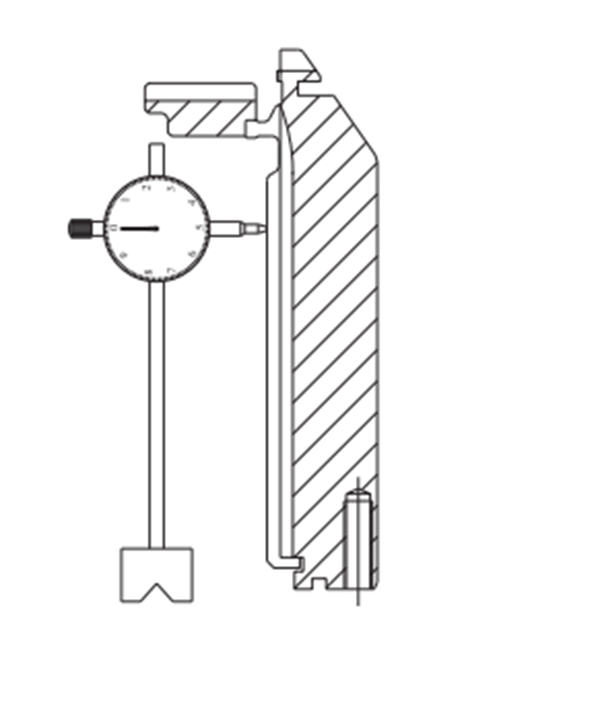

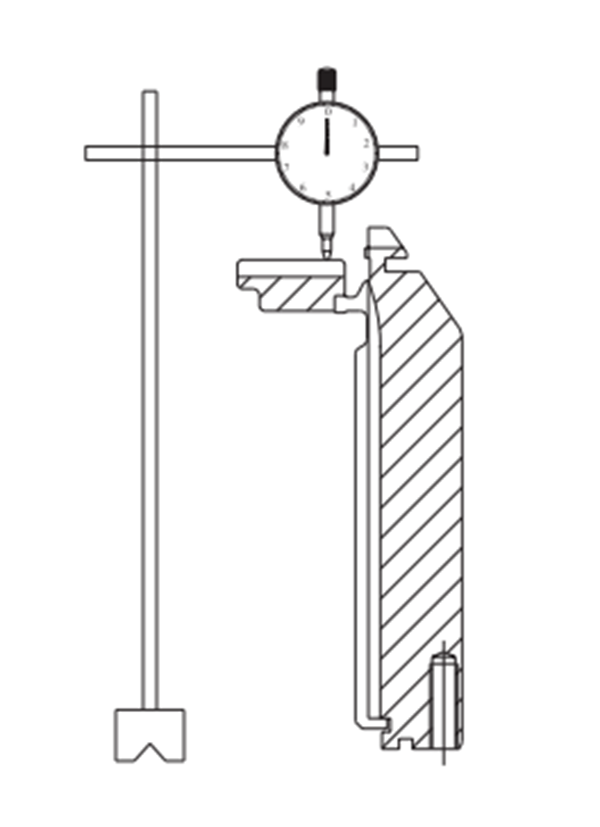

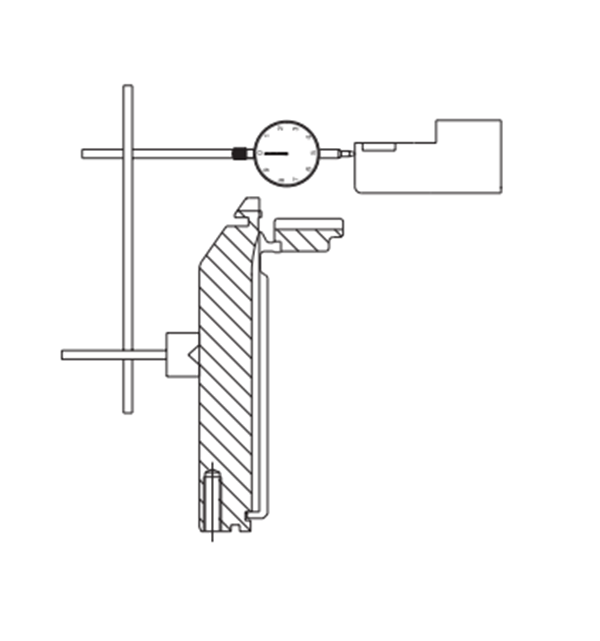

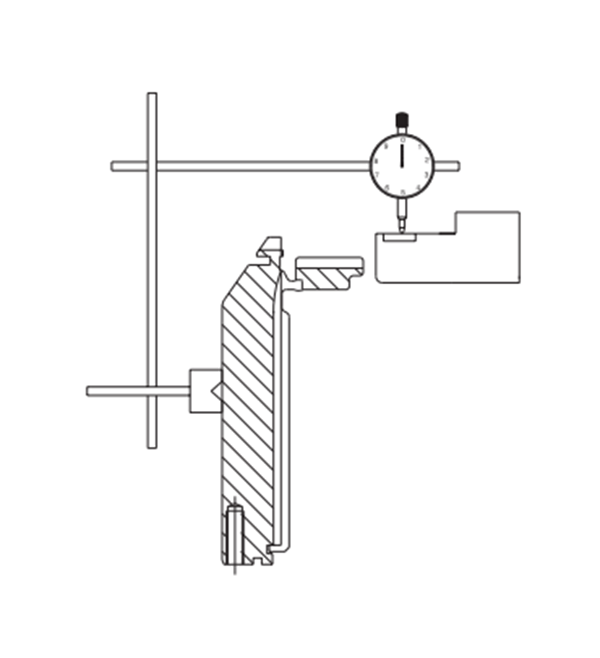

D、Adjustment of radial position of sinker

The sinker should be adjusted to the P position, and then the dial indicator should be fixed at the O position.

Loosen screw A to push the radial position of upper disc triangle forward or backward. Check the position of the sinker with a dial gauge.

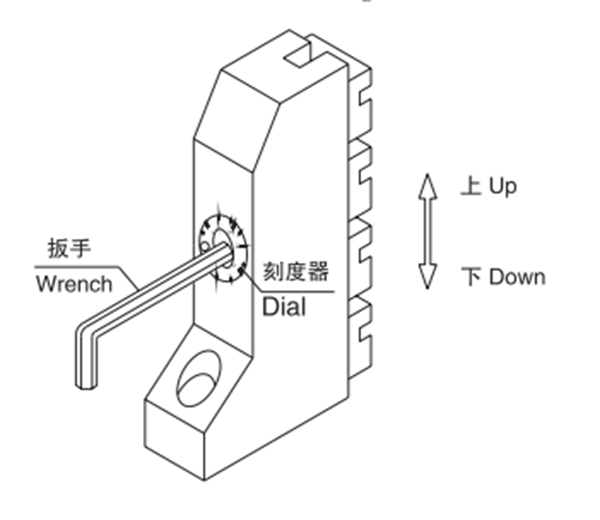

E、Needle height adjustment

a、Use a 6 mm Allen wrench to adjust the scale.

b、When the wrench rotates clockwise, the height of the knitting needle decreases; when it turns counterclockwise, the height of the knitting needle rises.

13RD:Technical Standard

The company’s products have been strictly inspected, adjusted, and tested. The no-load hot machine is no less than 48 hours, and the high-speed weaving pattern fabric is no less than 8 catties. The data file of the machine has been established, and it can be manufactured according to user requirements.

1、cylinder concentricity (roundness)

standard≤0.05mm

2、cylinder Parallelism

standard≤0.05mm

3. Parallelism of upper plate

standard≤0.05mm

5. Coaxiality (roundness) of the upper plate

standard≤0.05mm

14TH:Knitting mechanism

Circular knitting machines can be classified by needle type, number of cylinders, configuration of cylinders and needle movement.

The circular knitting machine is mainly composed of a yarn feeding mechanism, a weaving mechanism, a pulling-coiling mechanism and a transmission mechanism. The function of the yarn feeding mechanism is to unwind the yarn from the bobbin and transport it to the weaving area, which is divided into three types: negative type, positive type and storage type. Negative yarn feeding is to draw the yarn from the bobbin by tension and send it to the weaving area which is simple in structure and yarn feeding uniformity is poor. Positive yarn feeding is to actively deliver yarn to the knitting area at a constant linear speed. The advantages are uniform yarn feeding and small tension fluctuations, which help to improve the quality of knitted fabrics. The storage type yarn feeding is to unwind the yarn from the bobbin to the yarn storage bobbin by the rotation of the yarn storage bobbin, and the yarn is drawn out from the yarn storage bobbin by tension and enters the knitting area. Since the yarn is stored on the storage bobbin for a short period of relaxation, it is unwound from the fixed-diameter yarn storage bobbin, so it can eliminate the tension of the yarn caused by the different yarn capacity of the bobbin and the different unwinding points.

The function of the knitting mechanism is to weave the yarn into a cylindrical fabric through the work of the knitting machine. The knitting mechanism unit that can independently form the fed yarn into a loop is called a knitting system, commonly known as “Feeder”. Circular knitting machines are generally equipped with many Feeders.

The knitting mechanism includes knitting needles, yarn guides, sinkers, pressing steel plates, cylinders and cams, etc. The knitting needles are placed on the cylinders. There are two types of cylinder, rotary and fixed. In the latch needle circular machine, when the rotating cylinder brings the latch needle in the cylinder slot to the fixed cam, the cam pushes the needle butt to move the latch needle and weave the yarn into a loop. This method is conducive to increasing the speed of the vehicle and is widely used. When the cylinder is fixed, the latch needle is pushed by the cam rotating around the cylinder to form a loop. This method is convenient to change the cam position during operation, but the vehicle speed is relatively slow. Needle rotates with the cylinder, and the sinker drives the yarn, so that the yarn and the needle make relative motion to form a loop.

15TH:Adjustment of Yarn Feeding Aluminum Disc

Micro adjustment: When adjusting the diameter of the yarn feeding wheel,loosen the fastening nut on the top of the aluminum disc.

Note that when the top cover rotates, it should be kept as horizontal as possible, otherwise the tooth belt will fall out of the groove of the yarn feeding wheel.

In addition, while adjusting the diameter of the yarn feeding wheel, the tension of the tension rack tooth belt should also be adjusted. Belt tension adjustment.

If the tension of the tooth belt is too loose, the yarn feeding wheel and the tooth belt will slip, eventually resulting in yarn breakage and waste cloth.

Adjust the belt tension as follows:

Adjustment steps: Loosen the fastening screw of the tension frame, adjust the position of the transmission wheel to change the tension of the dental belt.

Note: Every time the diameter of the yarn feed wheel is changed, the tension of the tooth belt must be adjusted accordingly.

16TH:Fabric take down system

The function of the fabric take down mechanism is to use a pair of rotating pulling rollers to clamp the gray cloth, draw the newly formed fabric from the loop forming area, and wind it into a certain form of package. According to the rotation mode of the pulling roller, the fabric take down mechanism is divided into two types: intermittent type and continuous type. Intermittent stretching is divided into Positive stretching and Negative stretching. The pulling roller rotates at a certain angle at regular intervals. If the amount of rotation has nothing to do with the tension of the gray fabric, it is called Positive stretching, while if the amount of rotation is restricted by the tension of the gray fabric, it is called Negative stretching. In the continuous pulling mechanism, the pulling roller rotates at a constant speed, so it is also a positive pulling.

In some circular knitting machine, a needle selection mechanism is also installed for weaving the design and color organization. The designed pattern information is stored in a certain device, and then the knitting needles are put into work according to a certain procedure through the transmission mechanism.

The theoretical output of a circular knitting machine mainly depends on factors such as speed,gauge,diameter,feeder, fabric structure parameters and yarn fineness, which can be expressed by the output factor=cylinder speed (rev/ points) × cylinder diameter (cm/2.54) × number of feeder. The circular knitting machine has greater adaptability to the processing of yarns, and can weave a wide variety of designs and colors, and can also weave single-piece partially finished garment pieces. The machine has a simple structure, is easy to operate, has a high output, and occupies a small area. It occupies a large proportion in knitting machines and is widely used in the production of inner and outer garments. However, the number of working needles in the cylinder cannot be increased or decreased to change the width of the gray cloth, the cutting consumption of the cylindrical gray cloth is relatively large.

Post time: Oct-23-2023