5TH: Ukugcinwa kwesistimu yemoto neyesekethe

Uhlelo lwe-motor kanye ne-circuit, oluwumthombo wamandla we-umshini wokuluka, kumele ihlolwe ngokucophelela njalo ukuze kugwenywe ukuwohloka okungadingekile. Nanka amaphuzu abalulekile alo msebenzi:

1. Hlola ukuthi umshini awuvuzi yini

2. Hlola ukuthi i-fuse kanye nebhulashi lekhabhoni lemoto yonakele yini (ama-VS Motors kanye nama-inverter motors angenayo ibhulashi lekhabhoni)

3. Hlola ukuthi iswishi ayisebenzi kahle yini

4. Hlola ukuthi izintambo zigugile futhi azikaxhunywanga yini

5. Hlola injini, xhuma umugqa, hlanza ama-bearings (ama-bearings) bese ufaka uwoyela wokugcoba.

6. Hlola amagiya afanele, isondo elihambisanayo kanye nama-pulley ebhande ohlelweni lokushayela, bese uhlola umsindo ongajwayelekile, ukuxega noma ukuguguleka.

7. Uhlelo lokususa: Hlola isisindo sikawoyela sebhokisi legiya kanye ngenyanga, bese ufaka ngesibhamu sikawoyela.

Sebenzisa igrisi yokugcoba engu-2# MOBILUX; noma igrisi yokugcoba engu-SHELL ALVANIL 2#; noma igrisi yokugcoba enezinjongo eziningi ye-WYNN. Noma bheka “Incwadi Yemiyalelo Yohlelo Lokugoqa Indwangu”.

6TH: Ukulungiswa, ukuqoshwa kanye nokufakwa kwesivinini

1, Isivinini sokusebenzaumshiniisethwe, igcinwe ngekhanda futhi ilawulwa yi-inverter

2. Ukuze wenze isethingi, cindezela u-A ukuze uthuthukise idijithi eyodwa kanye no-V ukuze ubuyisele idijithi eyodwa emuva, Cindezela > ukuze uhambise isikhundla esisodwa ngakwesokudla. Ngemva kokuthi isethingi isiqediwe, cindezela i-DATA ukuze urekhode, bese umshini uzosebenza ngokwejubane lemiyalelo yakho.

3,Lapho umshiniiyasebenza, sicela ungacindezeli ngokungakhethi izinkinobho ezahlukahlukene ze-inverter.

4. Ukuze kusetshenziswe futhi kugcinwe kahle i-inverter, sicela ufunde “Incwadi Yemiyalelo Ne-Inverter” ngokuningiliziwe

7TH: I-Nozzle kawoyela

1, uhlobo lwe-Mist auto oiler

A、Xhuma indawo yokukhipha umoya ye-compressor emoyeni endaweni yokungena komoya ye-injector kaphethiloli ezenzakalelayo ngepayipi lepulasitiki, bese ufaka uwoyela wenaliti ethangini le-oiler ezenzakalelayo.

B、Lungisa i-air compressor kanye nokutholakala kwamafutha, isisindo samafutha kufanele sibe sikhulu uma umshini umusha, ukuze ungangcolisi indwangu.

C、Faka zonke izingxenye zepayipi likawoyela ngokuqinile, futhi uma uqala umshini, ungabona ukugeleza kukawoyela epayipini, okungukuthi, kuvamile.

D、Susa njalo indle esihlungini somoya.

2. I-oyela yezimoto kagesi

A、I-voltage yokusebenza ye-electronic auto oiler yi-AC 220±20V, 50MHZ.

B、^ Khetha inkinobho yesikhathi bese ucindezela kanye ukuze unyuse uhlaka olulodwa.

C. >Inkinobho yokuhambisa imbobo kawoyela, cindezela kanye ukuze uhambise igridi eyodwa, ihlukaniswe ngamaqembu amane e-ABCD.

3, Inkinobho yokusebenza yokusetha ye-SET/RLW, cindezela le nkinobho uma usetha kabusha, bese ucindezela le nkinobho uma usetha kabusha.

4. Zonke izinkinobho zokusetha zisethelwe ukucindezela lesi sikhiye ngesikhathi esisodwa.

5, isinqamuleli se-AU Cindezela lesi sihluthulelo ukuze wengeze uwoyela ngokushesha.

8: Isango lomshini

1. Elinye lamasango amathathu e-umshiniiyathuthwa ukuze igoqwe indwangu, futhi isango kumele liboshwe ngaphambi kokuba umshini usebenze.

2. Isango elihambayo lifakwe inzwa evimba isango ngokushesha lapho livulwa.

9TH: Isitholi senaliti

1. I-Needle detector izogxuma ngokushesha lapho inaliti yokuluka iphuka, futhi izoyidlulisela ngokushesha ohlelweni lokulawula, bese umshini uyeka ukusebenza zingakapheli imizuzwana engu-0.5.

2. Uma i-Needle iphuka, i-Needle detector ikhipha ukukhanya.

3. Ngemva kokushintsha inalithi entsha, sicela ucindezele i-needlebreaker ukuze uyisethe kabusha.

10TH: Idivayisi yokugcina intambo

1. Idivayisi yokugcina intambo idlala indima enhle ekondleni intambo kuumshini.

2. Uma uthango oluthile luphuka, ukukhanya okubomvu kwedivayisi yokugcina uthango kuzokhanya futhi umshini uzoyeka ukusebenza ngokushesha kungakapheli imizuzwana engu-0.5.

3. Kukhona amadivayisi okugcina intambo ahlukene nalawo angahlukaniswa. Idivayisi yokugcina intambo ehlukile ine-clutch, eqhutshwa phezulu yi-pulley engenhla bese yehla yi-pulley engezansi. Uma ubuyisela emuva intambo, qaphela ukuthi i-clutch ibambekile yini.

4. Uma kutholakala ukuthi i-lint iqoqana kudivayisi yokugcina intambo, kufanele ihlanzwe ngesikhathi.

11ST: Umqoqi wothuli lwe-radar

1. I-voltage yokusebenza ye-radar dust collector yi-AC220V.

2. Umqoqi wothuli lwe-radar uzojikeleza nomshini kuzo zonke izinhlangothi ukuze asuse i-lint lapho umshini uqalwa, futhi uzoyeka nokujikeleza lapho umshini uyeka.

3. Umqoqi wothuli lwe-radar ngeke ajikeleze uma inkinobho icindezelwa.

4. Kwabaqoqi bothuli be-radar, ibhokisi lokubuyela emuva elingaphezulu kweshafti ephakathi lifakwe amabhulashi e-carbon, kanti uthuli olusebhokisini lokubuyela emuva kufanele luhlanzwe ngugesi njalo ngekota.

Isaziso:

Ukuqina kwebhande kumele kulungiswe ngokufanele ububanzi besondo lokuphakela uboya isikhathi ngasinye.

12TH: Ukuhlolwa Kokuvunyelwa

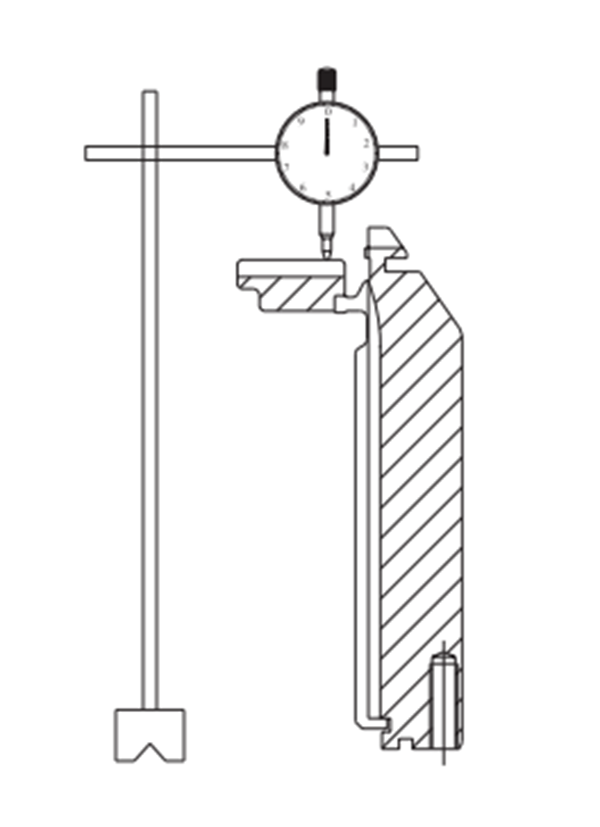

A、Sebenzisa i-feeler gauge ukuhlola igebe phakathi kwesilinda yenaliti nonxantathu wendilinga engezansi. Ububanzi begebe buphakathi kuka-0.2mm-0.30mm.

B、Isikhala esiphakathi kwesilinda yenaliti nonxantathu wepuleti elingaphezulu. Ububanzi besikhala buphakathi kuka-0.2mm-0.30mm.

Ukufakwa esikhundleni kwama-sinker:

Uma isinki idinga ukushintshwa, kungcono ukujika isinki ngesandla siye endaweni yokugoba. Khulula izikulufo, ususe ipuleti elingaphezulu, bese ushintsha isinki esidala.

C、Ukufakwa esikhundleni kwezinaliti:

Indawo ephakathi kwesibambo senaliti kanye ne-detector, indawo ye-detector kufanele ibe sesimweni esijwayelekile futhi inaliti yokuluka ingadlula kahle ngaphandle kokuma ngenxa yokuthinta i-detector. Ukukhetha inaliti kanye nokufakwa kwayo kufanele kuqaphele kakhulu, ukuze uphendule umshini ngesandla uye endaweni yomlomo, bese ususa inaliti enephutha phansi bese uyishintsha ngenaliti entsha.

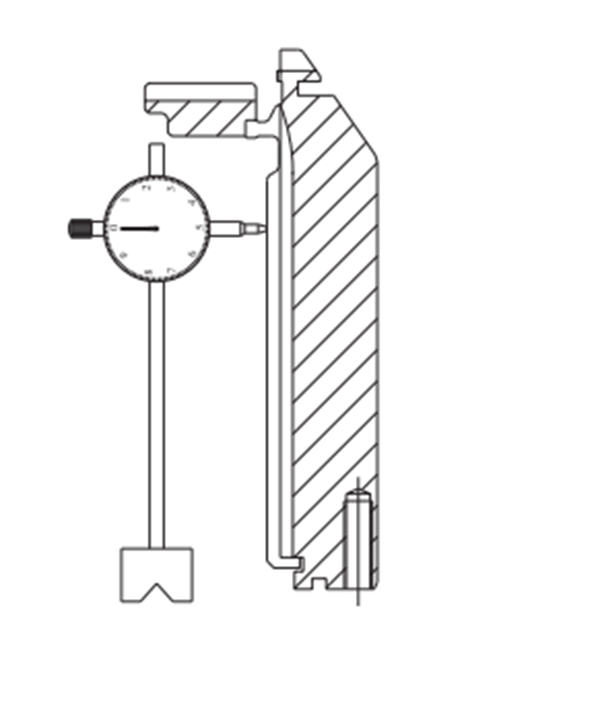

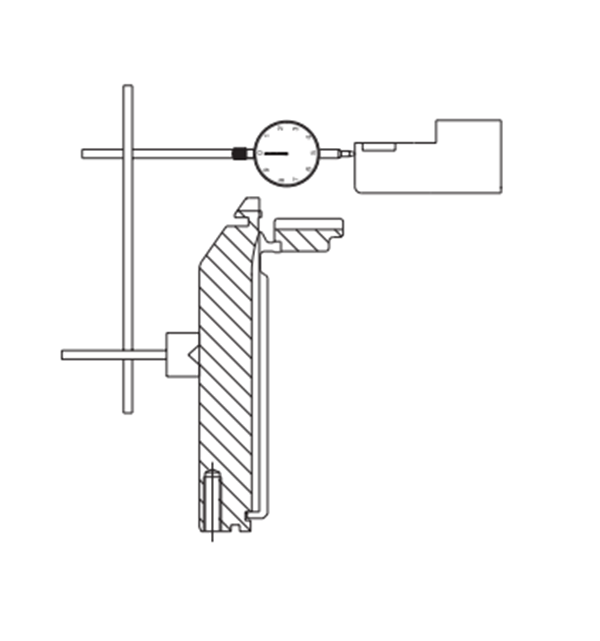

D、Ukulungiswa kwesikhundla se-radial sesinki

Isinki kufanele silungiswe sibe sesikhundleni sika-P, bese kuthi inkomba yokudayela ibekwe endaweni ka-O.

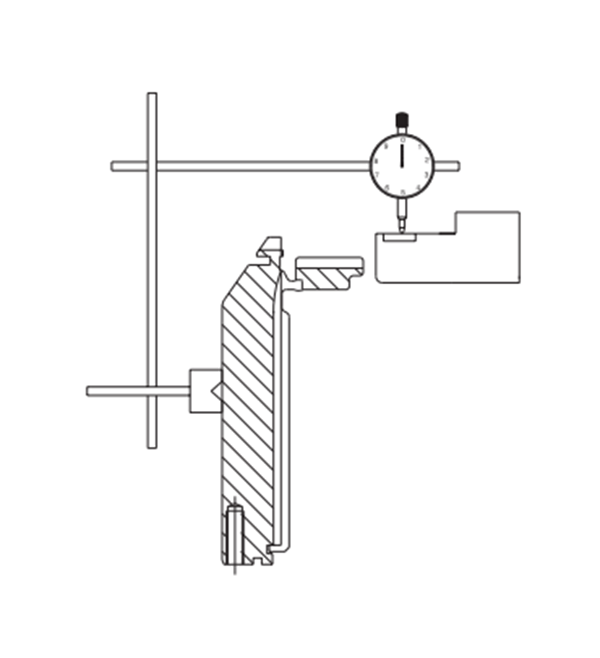

Khulula isikulufu u-A ukuze ucindezele indawo ye-radial ye-upper disc triangle phambili noma emuva. Hlola indawo ye-sinker nge-dial gauge.

E, ukulungiswa kokuphakama kwenaliti

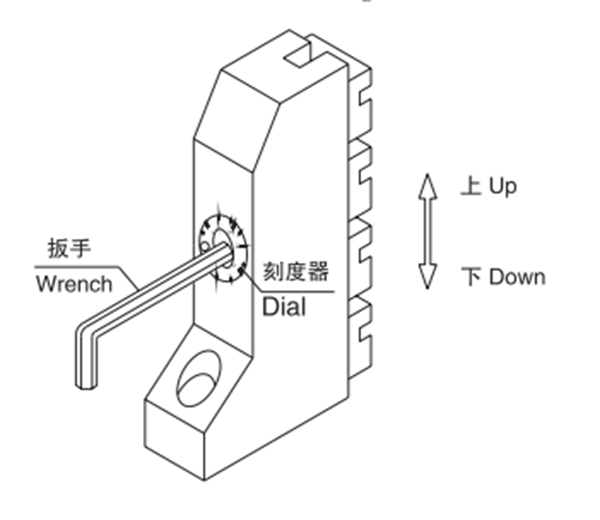

a、Sebenzisa isikrufu se-Allen esingu-6 mm ukulungisa isikali.

b、Uma isikrufu sijikeleza ngokwewashi, ukuphakama kwenaliti yokuluka kuyehla; uma iphenduka ngokuphambene newashi, ukuphakama kwenaliti yokuluka kuyenyuka.

13RD: Izinga Lobuchwepheshe

Imikhiqizo yenkampani ihlolwe ngokucophelela, yalungiswa, futhi yahlolwa. Umshini oshisayo ongathwali umthwalo uthatha okungenani amahora angu-48, kanti indwangu yokweluka ngesivinini esikhulu ithatha okungenani amahora angu-8. Ifayela ledatha lomshini selisunguliwe, futhi lingakhiqizwa ngokwezidingo zomsebenzisi.

1, ukuqina kwesilinda (ukuzungeza)

okujwayelekile ≤0.05mm

2, ukulingana kwesilinda

okujwayelekile ≤0.05mm

3. Ukufana kwepuleti eliphezulu

okujwayelekile ≤0.05mm

5. Ukujiya (ukuzungeza) kwepuleti eliphezulu

okujwayelekile ≤0.05mm

14TH:Indlela yokuthunga

Imishini yokuluka eyindilingaingahlukaniswa ngohlobo lwenaliti, inani lamasilinda, ukuhlelwa kwamasilinda kanye nokunyakaza kwenaliti.

Iumshini wokuluka oyindilingaYakhiwe kakhulu ngendlela yokondla ngentambo, indlela yokweluka, indlela yokudonsa nokubopha kanye nendlela yokudlulisa. Umsebenzi wendlela yokondla ngentambo ukukhipha intambo kusuka ku-bobbin bese uyithutha uye endaweni yokweluka, ehlukaniswe ngezinhlobo ezintathu: uhlobo olubi, uhlobo oluhle kanye nohlobo lokugcina. Ukondla ngentambo olubi ukudonsa intambo kusuka ku-bobbin ngokuyicindezela bese uyithumela endaweni yokweluka okulula ngesakhiwo futhi ukufana kokudla ngentambo akukuhle. Ukondla ngentambo okuhle ukuletha intambo ngenkuthalo endaweni yokweluka ngesivinini esiqondile. Izinzuzo ukondla ngentambo efanayo kanye nokushintshashintsha okuncane kokucindezeleka, okusiza ukuthuthukisa ikhwalithi yezindwangu ezithungiwe. Ukondla ngentambo yohlobo lokugcina ukukhulula intambo kusuka ku-bobbin kuya ku-bobbin yokugcina intambo ngokujikeleza kwe-bobbin yokugcina intambo, futhi intambo ikhishwa ku-bobbin yokugcina intambo ngokuyicindezela bese ingena endaweni yokweluka. Njengoba intambo igcinwa ku-bobbin yokugcina isikhathi esifushane sokuphumula, iyasuswa ku-bobbin yokugcina intambo enobubanzi obungaguquki, ngakho-ke ingasusa ukucindezeleka kwentambo okubangelwa amandla ahlukene entambo ye-bobbin kanye namaphuzu ahlukene okuqaqa.

Umsebenzi womshini wokuluka uwukuluka intambo ibe yindwangu esindayo ngomsebenzi womshini wokuluka. Iyunithi yomshini wokuluka engakha intambo ephakelwayo ibe yiluphu ibizwa ngokuthi uhlelo lokuluka, olwaziwa kakhulu ngokuthi “i-Feeder”. Imishini yokuluka eyindilinga ngokuvamile ifakwe ama-Feeder amaningi.

Indlela yokuluka ihlanganisa izinaliti zokuluka, iziqondiso zentambo, izinki, amapuleti ensimbi acindezelayo, amasilinda nama-cam, njll. Izinaliti zokuluka zifakwa kumasilinda. Kunezinhlobo ezimbili zesilinda, ezijikelezayo nezilungisiwe. Emshinini oyindilinga wenaliti yokulahlela, lapho isilinda esijikelezayo siletha inaliti yokulahlela endaweni yesilinda ku-cam elungisiwe, i-cam isunduza isinqe senaliti ukuze ihambise inaliti yokulahlela bese iluke intambo ibe yiluphu. Le ndlela ilungele ukwandisa ijubane lemoto futhi isetshenziswa kabanzi. Lapho isilinda silungisiwe, inaliti yokulahlela isunduzwa yi-cam ejikeleza isilinda ukuze yakhe iluphu. Le ndlela ilula ukushintsha isikhundla se-cam ngesikhathi sokusebenza, kodwa ijubane lemoto lihamba kancane. Inaliti ijikeleza nesilinda, futhi isinki ishayela intambo, ukuze intambo nenaliti zenze ukunyakaza okuhlobene ukuze kwakheke iluphu.

15TH: Ukulungiswa kweDiski ye-Aluminium Yokuphakela Intambo

Ukulungiswa okuncane: Uma ulungisa ububanzi besondo lokudla ngentambo, khulula i-fastening nut phezulu kwediski ye-aluminium.

Qaphela ukuthi uma isembozo sangaphezulu sijikeleza, kufanele sigcinwe sivundlile ngangokunokwenzeka, ngaphandle kwalokho ibhande lamazinyo lizowa liphume emseleni wesondo lokudla uboya.

Ngaphezu kwalokho, ngenkathi kulungiswa ububanzi besondo lokudla ngentambo, ukuqina kwebhande lamazinyo le-tension rack kufanele kulungiswe. Ukulungiswa kokuqina kwebhande.

Uma ukucindezeleka kwebhande lamazinyo kukhulu kakhulu, isondo lokudla uboya kanye nebhande lamazinyo kuzoshelela, ekugcineni kuholele ekuphukeni koboya kanye nendwangu elahliwe.

Lungisa ukuqina kwebhande kanje:

Izinyathelo zokulungisa: Khulula isikulufu sokubopha sohlaka lokucindezela, lungisa indawo yesondo lokudlulisa ukuze ushintshe ukucindezeleka kwebhande lamazinyo.

Qaphela: Njalo uma ububanzi besondo lokuphakelayo lentambo bushintshwa, ukuqina kwebhande lamazinyo kumele kulungiswe ngokufanele.

16: Uhlelo lokususa indwangu

Umsebenzi wendlela yokususa indwangu ukusebenzisa ama-roller amabili ajikelezayo okudonsa ukuze abambe indwangu empunga, adonse indwangu esanda kwakheka endaweni yokwakha iluphu, bese eyisonga ibe uhlobo oluthile lwephakheji. Ngokwendlela yokujikeleza ye-roller yokudonsa, indlela yokususa indwangu ihlukaniswe izinhlobo ezimbili: uhlobo oluqhubekayo nohlobo oluqhubekayo. Ukwelula okuphakathi kuhlukaniswe kube ukwelula okuqondile kanye nokwelula okungalungile. I-roller yokudonsa ijikeleza nge-engeli ethile ngezikhathi ezijwayelekile. Uma inani lokujikeleza lingahlobene nokucindezeleka kwendwangu empunga, libizwa ngokuthi ukwelula okuqondile, kanti uma inani lokujikeleza livinjelwe ukucindezelwa kwendwangu empunga, libizwa ngokuthi ukwelula okungalungile. Endleleni yokudonsa okuqhubekayo, i-roller yokudonsa ijikeleza ngesivinini esingaguquki, ngakho-ke futhi iwukudonsa okuhle.

Kwezinyeumshini wokuluka oyindilinga, kufakwe nendlela yokukhetha inaliti yokuthunga umklamo kanye nokuhleleka kombala. Ulwazi lwephethini oluklanyiwe lugcinwa kudivayisi ethile, bese izinaliti zokuluka zifakwa emsebenzini ngokwenqubo ethile ngokusebenzisa indlela yokudlulisa.

Umphumela wemfundiso womshini wokuluka oyindilinga uncike kakhulu ezintweni ezifana nesivinini, igeyiji, ububanzi, i-feeder, amapharamitha esakhiwo sendwangu kanye nobukhulu bendwangu, okungavezwa yi-output factor=isivinini sesilinda (rev/points) × ububanzi besilinda (cm/2.54) × inani le-feeder. Umshini wokuluka oyindilinga unokuzivumelanisa okukhulu nokucutshungulwa kwendwangu, futhi ungaluka imiklamo nemibala eyahlukahlukene, futhi ungaluka nezingcezu zengubo eziqediwe kancane. Umshini unesakhiwo esilula, kulula ukuwusebenzisa, unomkhiqizo ophezulu, futhi uhlala endaweni encane. Uhlala ingxenye enkulu emishinini yokuluka futhi usetshenziswa kabanzi ekukhiqizeni izingubo zangaphakathi nezangaphandle. Kodwa-ke, inani lezinaliti ezisebenzayo esilinda alikwazi ukwanda noma ukwehla ukuze kushintshwe ububanzi bendwangu empunga, ukusetshenziswa kokusika kwendwangu empunga eyindilinga kukhulu kakhulu.

Isikhathi sokuthunyelwe: Okthoba-23-2023