5TH: Ukugcinwa kwemoto kunye nenkqubo yesekethe

Inkqubo yemoto kunye neyesekethe, engumthombo wamandla weumatshini wokuluka, kufuneka ihlolwe rhoqo ngokungqongqo ukuze kuthintelwe ukonakala okungeyomfuneko. Nazi izinto eziphambili zomsebenzi:

1, Jonga ukuba umatshini awuvuzi na

2. Jonga ukuba i-fuse kunye nebrashi yekhabhoni yemoto zonakele na (ii-VS Motors kunye nee-inverter motors ezingenayo ibrashi yekhabhoni)

3, Jonga ukuba iswitshi ayisebenzi kakuhle na

4. Jonga ukuba iingcingo zigugile kwaye azikhuphi na

5. Jonga i-motor, qhagamshela umgca, coca iibheringi (iibheringi) uze wongeze ioyile yokuthambisa

6. Jonga iigiya ezifanelekileyo, ivili elihambelanayo kunye neepulley zebhanti kwinkqubo yokuqhuba, kwaye ujonge ingxolo engaqhelekanga, ukukhululeka okanye ukuguguleka.

7. Inkqubo yokuyisusa: Jonga ubunzima beoyile yebhokisi yegiya kube kanye ngenyanga, uze uyifake ngesibhamu seoyile.

Sebenzisa igrisi yokuthambisa ye-MOBILUX eyi-2#; okanye igrisi yokuthambisa ye-SHELL ALVANIL 2#; okanye igrisi yokuthambisa ye-WYNN eneenjongo ezininzi. Okanye bhekisa kwi-"Incwadi Yemiyalelo yenkqubo yokuqengqeleka kwelaphu".

6TH: Uhlengahlengiso, ukurekhoda kunye nokufaka isantya

1, Isantya sokusebenzaumatshiniisetiwe, igcinwe ngentloko kwaye ilawulwa yi-inverter

2. Ukwenza useto, cofa u-A ukuze uqhubele phambili idijithi enye kunye no-V ukuze ubuyisele idijithi enye, cofa u-> ukuze uhambise indawo enye uye ngasekunene. Emva kokuba useto lugqityiwe, cofa u-DATA ukuze urekhode, kwaye umatshini uya kusebenza ngokwesantya somyalelo wakho.

3,Xa umatshiniiyasebenza, nceda ungacinezeli ngokungenamkhethe amaqhosha ahlukeneyo e-inverter.

4. Ukuze kusetyenziswe kwaye kugcinwe i-inverter, nceda ufunde “Incwadi yemiyalelo ye-Inverter kunye nemiyalelo” ngokweenkcukacha.

7TH: Impumlo yeoyile

1, uhlobo lwe-oyile yemoto yohlobo lwe-Mist

A、Qhagamshela indawo yokukhupha umoya yecompressor yomoya kwindawo yokungena yomoya ye-automatic fuel injector ngetyhubhu yeplastiki, uze wongeze ioyile yenaliti kwitanki ye-auto oiler.

B、Lungisa i-air compressor kunye nombane weoyile, ubunzima beoyile kufuneka bube bukhulu xa umatshini umtsha, ukuze ungangcolisi ilaphu.

C、Faka zonke iindawo zetyhubhu yeoyile ngokuqinileyo, kwaye xa uqala umatshini, ungabona ukuhamba kweoyile kwityhubhu, oko kukuthi, kuyinto eqhelekileyo.

D、Susa amanzi amdaka rhoqo kwisihluzi somoya.

2, i-oiler ye-elektroniki yemoto

A、I-voltage yokusebenza ye-electronic auto oiler yi-AC 220±20V, 50MHZ.

B、^ Khetha iqhosha lexesha uze ucinezele kube kanye ukuze unyuse ifreyimu enye.

C. >Isitshixo sokuhamba somngxuma weoyile, cinezela kube kanye ukuhambisa igridi enye, yahlulwe yangamaqela amane e-ABCD.

3, Isitshixo sokuSebenza seSETI/RLW, cinezela eli qhosha xa useta kwakhona, kwaye ucinezele eli qhosha xa useta kugqityiwe.

4, Zonke izitshixo zokuseta zimiselwe ukucinezela eli qhosha ngaxeshanye

5, indlela emfutshane ye-AU Cinezela eli qhosha ukuze wongeze ioyile ngokukhawuleza.

8TH: Isango lomatshini

1. Elinye lamasango amathathu e-umatshiniiyashukunyiswa ukuze iqengqelwe ilaphu, kwaye isango kufuneka libotshelelwe ngaphambi kokuba umatshini usebenze.

2. Isango elinokushukuma lixhotyiswe ngesixhobo sokuvavanya isango esimisa isango ngoko nangoko xa livuliwe.

I-9TH: Isikhangeli senaliti

1. Isixhobo sokubona inaliti siza kuphuma ngoko nangoko xa inaliti yokuluka iphukile, size siyithumele ngokukhawuleza kwinkqubo yolawulo, kwaye umatshini uya kuyeka ukusebenza kwimizuzwana eyi-0.5.

2. Xa iNeedle iphuka, isixhobo sokubona iNeedle sikhupha ukukhanya okukhanyayo.

3. Emva kokutshintsha inaliti entsha, nceda ucinezele i-needle breaker ukuze uyiqalise kwakhona.

10TH: Isixhobo sokugcina intambo

1. Isixhobo sokugcina intambo sidlala indima entle ekondleni intamboumatshini.

2. Xa intambo ethile iphukile, isibane esibomvu sesixhobo sokugcina intambo siya kukhazimla kwaye umatshini uya kuyeka ukusebenza ngokukhawuleza kwimizuzwana eyi-0.5.

3. Kukho izixhobo zokugcina intambo ezahlukeneyo nezingahlukaniswayo. Isixhobo sokugcina intambo esahlukileyo sine-clutch, eqhutywa phezulu yi-pulley ephezulu ize ihliswe yi-pulley esezantsi. Xa ubuyisela umva intambo, qaphela ukuba i-clutch ibambekile na.

4. Xa kufunyaniswa ukuba i-lint iqokelelana kwisixhobo sokugcina intambo, kufuneka icocwe ngexesha elifanelekileyo.

11ST: Umqokeleli wothuli lweradar

1. I-voltage yokusebenza yomqokeleli wothuli lweradar yi-AC220V.

2. Umqokeleli wothuli lweradar uza kujikeleza nomatshini kuzo zonke iindlela ukuze asuse i-lint xa umatshini uqaliswa, kwaye uza kuyeka ukujikeleza xa umatshini uyeka.

3. Umqokeleli wothuli lweradar akayi kujika xa iqhosha licinezelwe.

4. Kwabaqokeleli bothuli lweradar, ibhokisi yokubuyisela umva ephezu kweshaft ephakathi ixhotyiswe ngeebhrashi zekhabhoni, kwaye uthuli olukwibhokisi yokubuyisela umva kufuneka lucocwe ngumbane rhoqo ngekota.

Isaziso:

Uxinzelelo lwebhanti kufuneka lulungiswe ngokufanelekileyo ngokobubanzi bevili lokutya intambo ngalo lonke ixesha.

12TH: Ukuhlolwa kokuVunywa

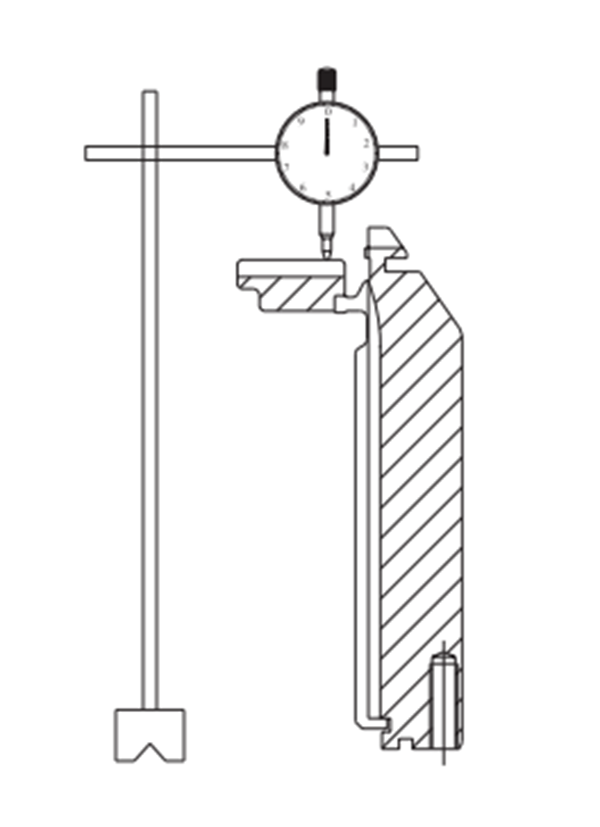

A、Sebenzisa i-feeler gauge ukujonga umsantsa phakathi kwesilinda yenaliti kunye nonxantathu wesangqa esisezantsi. Uluhlu lomsantsa luphakathi kwe-0.2mm-0.30mm.

B、Umsantsa ophakathi kwesilinda yenaliti kunye nonxantathu wepleyiti ephezulu. Uluhlu lomsantsa luphakathi kwe-0.2mm-0.30mm.

Ukutshintshwa kwee-sinkers:

Ukuba isinki kufuneka itshintshwe, kungcono ukuyijika ngesandla isinki iye kwindawo yenotshi. Khulula izikrufu, ususe ipleyiti engaphezulu, uze emva koko utshintshe isinki endala.

C, Ukutshintshwa kweenaliti:

Indawo ephakathi kwelatch yenaliti kunye ne-detector, indawo ye-detector kufuneka ibe kwindawo eqhelekileyo kwaye inaliti yokuluka ingadlula kakuhle ngaphandle kokuma ngenxa yokuchukumisa i-detector. Ukukhetha inaliti kunye nokufakelwa kwayo kufuneka kuqapheleke kakhulu, ukujika umatshini ngesandla uye emlonyeni, uze ususe inaliti ephosakeleyo ezantsi uze uyitshintshe ngenaliti entsha.

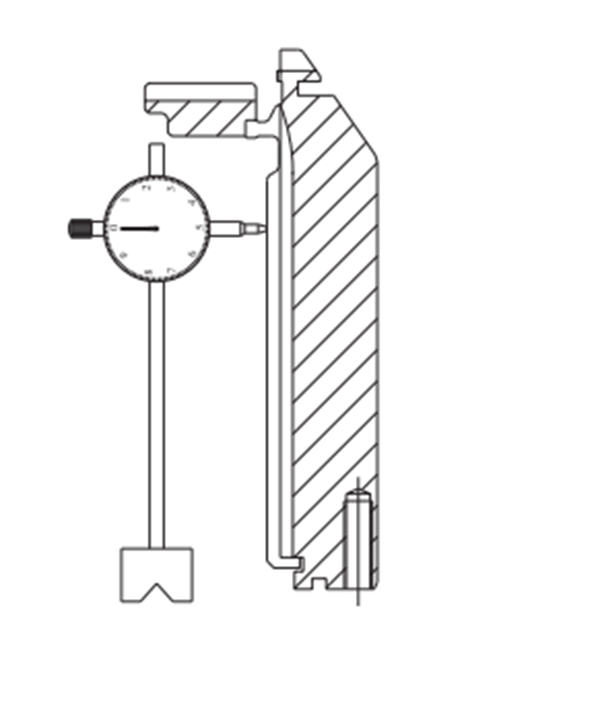

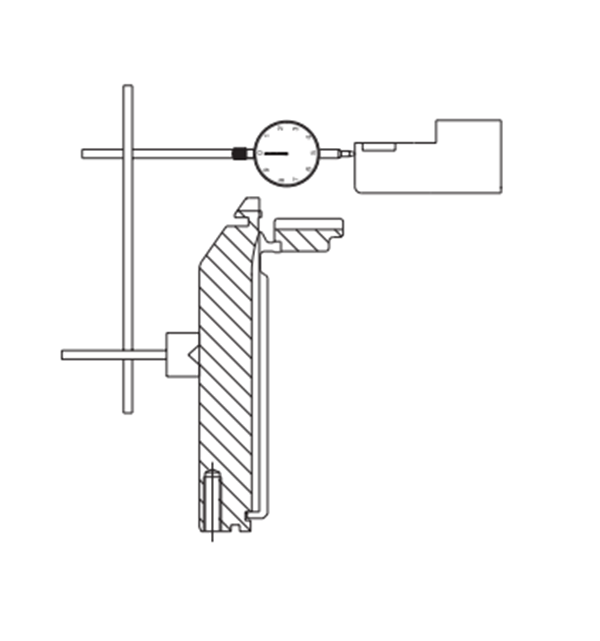

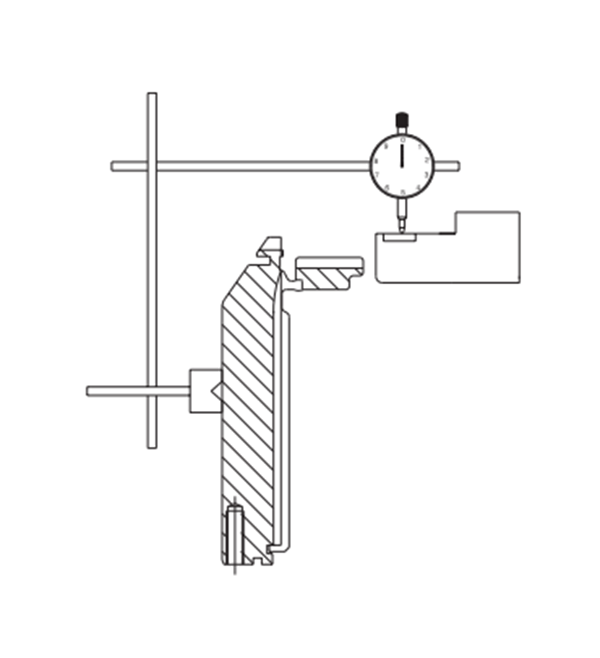

D、Ukulungiswa kwendawo ye-radial yesinki

Isinki kufuneka ilungiswe ihambelane nendawo ye-P, kwaye emva koko isalathisi sokudayela kufuneka simiselwe kwindawo ye-O.

Khulula isikrufu u-A ukuze utyhale indawo ye-radial yediski ephezulu unxantathu phambili okanye ngasemva. Jonga indawo yesinki nge-dial gauge.

E, uhlengahlengiso lokuphakama kwenaliti

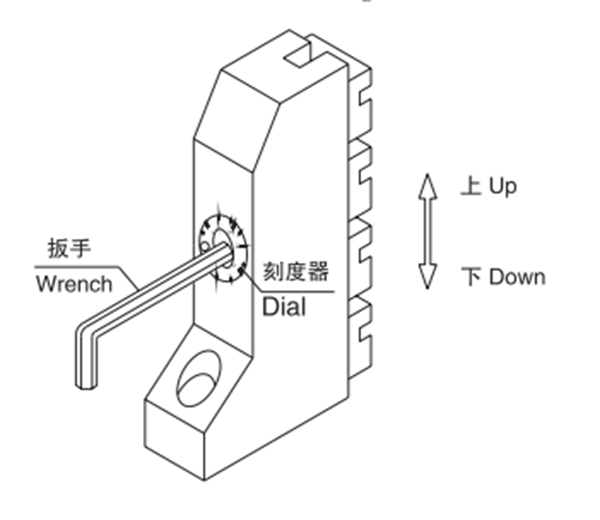

a、Sebenzisa isikrufu se-Allen esingu-6 mm ukulungisa isikali.

b、Xa isikrufu sijikeleza ngokwewotshi, ukuphakama kwenaliti yokuluka kuyehla; xa ijika ngokuchasene newotshi, ukuphakama kwenaliti yokuluka kuyenyuka.

13RD: Umgangatho woBugcisa

Iimveliso zenkampani zihlolwe ngokungqongqo, zalungiswa, zaza zavavanywa. Umatshini oshushu ongenamthwalo uthatha iiyure ezingama-48, kwaye ilaphu lepatheni yokwaluka elikhawulezayo lithatha iiyure ezi-8. Ifayile yedatha yomatshini sele imiselwe, kwaye inokwenziwa ngokweemfuno zomsebenzisi.

1, isilinda concentricity (ubungqukuva)

umgangatho ≤0.05mm

2, isilinda Ukufana

umgangatho ≤0.05mm

3. Ukufana kwepleyiti ephezulu

umgangatho ≤0.05mm

5. Ukuxinana kwepleyiti ephezulu

umgangatho ≤0.05mm

14TH:Indlela yokuluka

Oomatshini bokuluka abajikelezayoinokuhlelwa ngohlobo lwenaliti, inani leesilinda, ulwakhiwo lweesilinda kunye nokuhamba kwenaliti.

Iumatshini wokuluka ojikelezayoIkakhulu yenziwe ngendlela yokondla intambo, indlela yokuluka, indlela yokutsala kunye nendlela yokudlulisa. Umsebenzi wendlela yokondla intambo kukukhulula intambo kwi-bobbin uze uyithuthe uye kwindawo yokuluka, eyahlulwe yangamaqela amathathu: uhlobo olubi, uhlobo oluhle kunye nohlobo lokugcina. Ukondla intambo olubi kukutsala intambo kwi-bobbin ngokuxinzelela kwaye uyithumele kwindawo yokuluka elula kwaye ukufana kokutya intambo akukuhle. Ukondla intambo elungileyo kukuhambisa intambo kwindawo yokuluka ngesantya esilinganayo. Iingenelo kukondla intambo efanayo kunye nokuguquguquka okuncinci kokuxinzelela, okunceda ukuphucula umgangatho wamalaphu anithiweyo. Ukondla intambo yohlobo lokugcina kukukhulula intambo ukusuka kwi-bobbin ukuya kwi-bobbin yokugcina intambo ngokujikeleza kwe-bobbin yokugcina intambo, kwaye intambo ikhutshwa kwi-bobbin yokugcina intambo ngokuxinzelela kwaye ingene kwindawo yokuluka. Ekubeni intambo igcinwa kwi-bobbin yokugcina ixesha elifutshane lokuphumla, ayisuswa kwi-bobbin yokugcina intambo enobubanzi obumiselweyo, ngoko ke inokuphelisa uxinzelelo lwentambo olubangelwa kumthamo owahlukileyo wentambo ye-bobbin kunye neendawo ezahlukeneyo zokuvuleka.

Umsebenzi wendlela yokuluka kukuluka intambo ibe ngelaphu eliyi-cylindrical ngokusebenzisa umatshini wokuluka. Iyunithi yendlela yokuluka enokwenza intambo eyondliweyo ibe yiluphu ibizwa ngokuba yinkqubo yokuluka, eyaziwa ngokuba yi-"Feeder". Oomatshini bokuluka abajikelezayo ngokubanzi baxhotyiswe ngeeFeeder ezininzi.

Indlela yokuluka ibandakanya iinaliti zokuluka, izikhokelo zemisonto, izitya zokusinkisha, iipleyiti zentsimbi ezicinezelayo, iisilinda kunye neekam, njl. Iinaliti zokuluka zibekwe kwiisilinda. Kukho iintlobo ezimbini zesilinda, ezijikelezayo nezilungisiweyo. Kumatshini ojikelezayo wenaliti yokusinkisha, xa isilinda esijikelezayo sizisa inaliti yokusinkisha kwindawo yesilinda kwikam elungisiweyo, ikham ityhala inaliti yokusinkisha ukuhambisa inaliti yokusinkisha kwaye iluke intambo ibe yiluphu. Le ndlela iluncedo ekwandiseni isantya sesithuthi kwaye isetyenziswa kakhulu. Xa isilinda ilungisiwe, inaliti yokusinkisha ityhalwa yikham ejikelezayo kwisilinda ukwenza iluphu. Le ndlela ilula ukutshintsha indawo yekham ngexesha lokusebenza, kodwa isantya sesithuthi sicotha kakhulu. Inaliti ijikeleza nesilinda, kwaye isinki iqhuba intambo, ukuze intambo kunye nenaliti zenze intshukumo ehambelanayo ukwenza iluphu.

15TH: Uhlengahlengiso lweDisiki yeAluminiyam yokuTya iNtambo

Uhlengahlengiso oluncinci: Xa ulungisa ububanzi bevili lokutya intambo, khulula i-fastening nut ephezu kwediski ye-aluminiyam.

Qaphela ukuba xa isigqubuthelo esingaphezulu sijikeleza, kufuneka sigcinwe sithe tyaba kangangoko kunokwenzeka, kungenjalo ibhanti yamazinyo iya kuwa ngaphandle komngxuma wevili lokutya intambo.

Ukongeza, ngelixa ulungisa ububanzi bevili lokutya intambo, uxinzelelo lwebhanti yamazinyo e-tension rack nalo kufuneka lulungiswe. Uhlengahlengiso loxinzelelo lwebhanti.

Ukuba uxinzelelo lwebhanti yamazinyo lukhululekile kakhulu, ivili lokutya intambo kunye nebhanti yamazinyo ziya kutyibilika, ekugqibeleni zibangele ukwaphuka kwentambo kunye nelaphu elilahliweyo.

Lungisa uxinzelelo lwebhanti ngolu hlobo lulandelayo:

Amanyathelo okulungisa: Khulula isikrufu sokubambelela kwisakhelo soxinzelelo, lungisa indawo yevili lokudlulisa ukuze utshintshe uxinzelelo lwebhanti yamazinyo.

Qaphela: Ngalo lonke ixesha ububanzi bevili lokutya kwentambo butshintshwa, uxinzelelo lwebhanti yamazinyo kufuneka lulungiswe ngokufanelekileyo.

16TH: Inkqubo yokususa ilaphu

Umsebenzi wendlela yokususa ilaphu kukusebenzisa iirola ezijikelezayo zokutsala ukuze zibambe ilaphu elingwevu, zitsale ilaphu elitsha kwindawo yokwenza iluphu, kwaye zilijike libe yipakethe ethile. Ngokwendlela yokujikeleza yerola yokutsala, indlela yokususa ilaphu yahlulwe yaba ziintlobo ezimbini: uhlobo oluphakathi kunye nohlobo oluqhubekayo. Ukolula okuphakathi kwahlulwe ngokwolula okuqinisekileyo kunye nokolula okungalunganga. Irola yokutsala ijikeleza nge-engile ethile ngamaxesha athile. Ukuba ubungakanani bokujikeleza abunanto yakwenza noxinzelelo lwelaphu elingwevu, kuthiwa kukolula okuqinisekileyo, ngelixa ukuba ubungakanani bokujikeleza buthintelwe kukuxinana kwelaphu elingwevu, kuthiwa kukolula okungalunganga. Kwindlela yokudonsa okuqhubekekayo, irola yokutsala ijikeleza ngesantya esingaguqukiyo, ngoko ke ikwakukolula okuqinisekileyo.

Kwezinyeumatshini wokuluka ojikelezayo, kufakelwe nendlela yokukhetha inaliti yokuluka uyilo kunye nokulungelelaniswa kombala. Ulwazi lwepateni oluyiliweyo lugcinwa kwisixhobo esithile, kwaye emva koko iinaliti zokuluka zifakwa emsebenzini ngokwenkqubo ethile ngokusebenzisa indlela yokudlulisa.

Imveliso yethiyori yomatshini wokuluka ojikelezayo ixhomekeke kakhulu kwizinto ezifana nesantya, igeyiji, ububanzi, i-feeder, iiparameter zesakhiwo selaphu kunye nobuhle bentambo, ezinokubonakaliswa yi-output factor=isantya sesilinda (rev/ points) × ububanzi besilinda (cm/2.54) × inani le-feeder. Umatshini wokuluka ojikelezayo unokukwazi ukulungelelanisa ngakumbi ukucutshungulwa kwentambo, kwaye unokuluka iintlobo ngeentlobo zoyilo kunye nemibala, kwaye unokuluka iziqwenga zengubo ezigqityiweyo kancinci. Umatshini unesakhiwo esilula, kulula ukuyisebenzisa, unomphumo ophezulu, kwaye uhlala kwindawo encinci. Uhlala inxalenye enkulu kumatshini wokuluka kwaye usetyenziswa kakhulu kwimveliso yezambatho zangaphakathi nezangaphandle. Nangona kunjalo, inani leenaliti ezisebenzayo kwisilinda alinakwandiswa okanye lincitshiswe ukutshintsha ububanzi belaphu elingwevu, ukusetyenziswa kwelaphu elingwevu eliyi-cylindrical kukhulu kakhulu.

Ixesha lokuthumela: Okthobha-23-2023