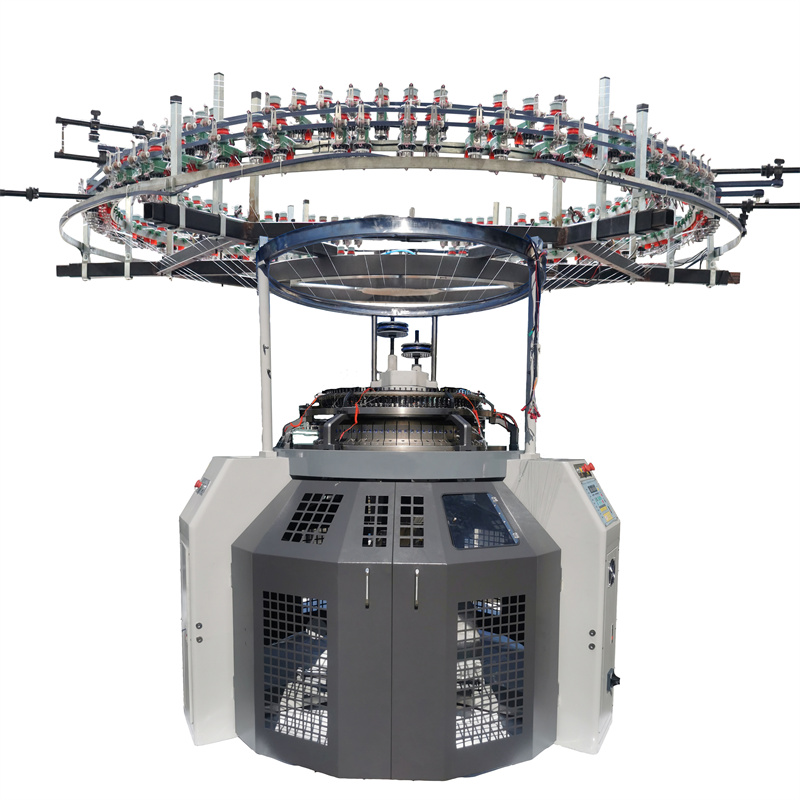

Single Reverse Plated Loop Circular Knitting Machine

Specification of Machine

The heart tissues of Single Reverse Plated Loop Circular Knitting Machine is consist of needle cylinder, knitting needle, sinker, cams, water chestnut, water chestnut seat, yarn feeding nozzle, yarn feeding ring, yarn feeding ring guidance, upper foot, water chestnut seat bottom ring, cam boxes saddle seat and saddle seat bottom ring.

The control panel of Single Reverse Plated Loop Circular Knitting Machine is generally divided into LCD LED and ordinary style. We can customize the control panel for you if we got the size, socket and brand of machine.

The dust exhausting fans of Single Reverse Plated Loop Circular Knitting Machine are respectively installed in the middle and at the top as well as bottom of the product so as to remove useless cotton fiber, protect sinkers and needles, and improve operating efficiency.

Single Reverse Plated Loop Circular Knitting Machine can knit Swimsuit fabric、High elastic spandex fabric.

Company profile

Our company has a R & D engineer team with 15 domestic engineers and 5 foreign designer to overcome the OEM design requirement for our customers, and innovate new technology and apply to our machines. And we have World Class advanced Accurate three-coordinate measuring instrument test to ensure the production Quality Inspection.

Exhibition

The exhibitions our company participated in include ITMA, SHANGHAITEX, Uzbekistan Exhibition (CAITME), Cambodia International Textile and Garment Machinery Exhibition (CGT), Vietnam Textile and Garment Industry Exhibition (SAIGONTEX), Bangladesh International Textile and Garment Industry Exhibition (DTG)

FAQ

1. Can your company identify the products that your company produces?

A: Our machine has a design patent for the appearance, and the painting process is special.

2.What are the differences between your products in the same industry?

A:The function of the computer is powerful (the top and bottom can do jacquard, transfer circle, and automatically separate the cloth)

3.What principle is the appearance of your products designed on? What are the advantages?

A:Mayer & Cie high speed that conforms to the human working curve

4. How long does your mold development take?

A:It usually takes 15-20 days. If the model is special, we need a week to prepare and one to two weeks to arrange the casting production.

![[Copy] Double Jersey 4/6 Colors Stripe Circular Knitting Machine](https://cdn.globalso.com/eastinoknittingmachine/xacacac-2-300x300.jpg)