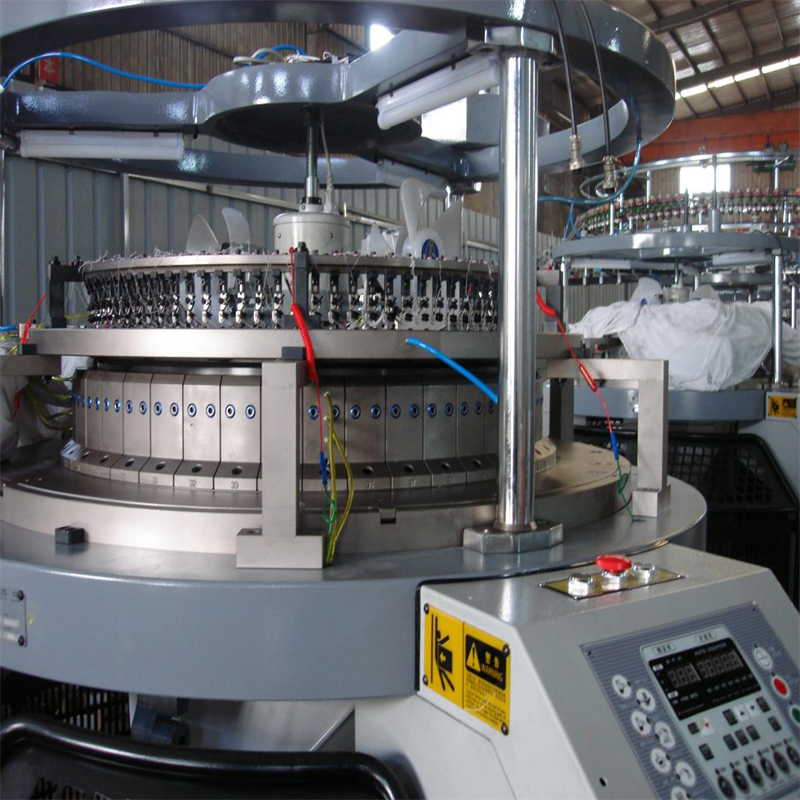

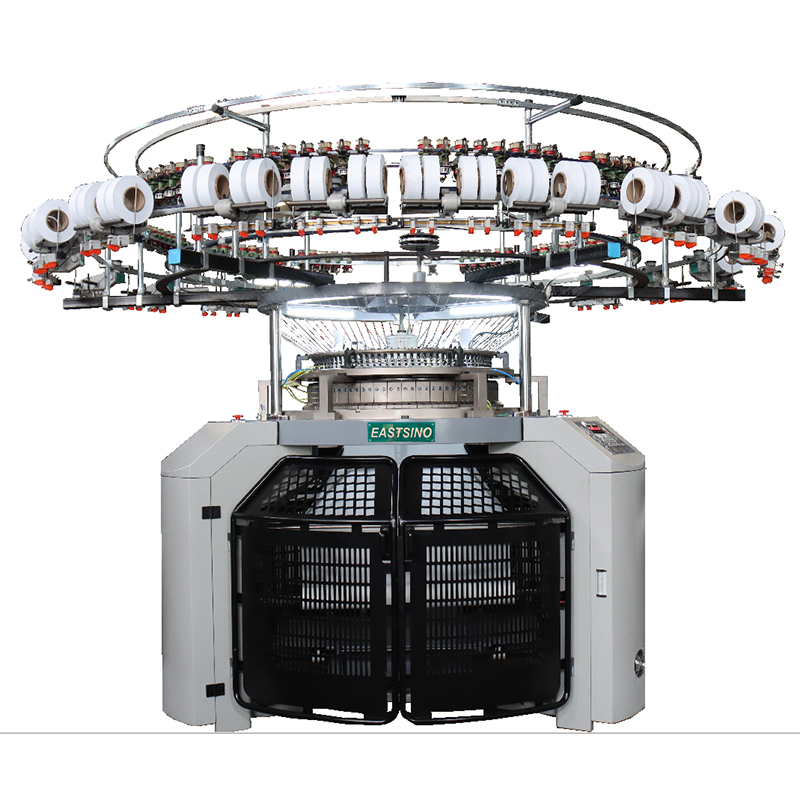

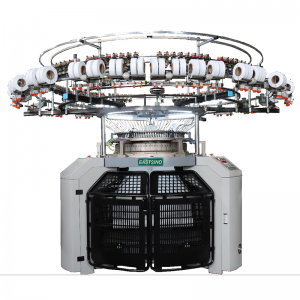

Single Jersey Circular Knitting Machine

Features

Single Jersey Circular Knitting Machine adopts closed 4 tracks Cam design with cams of knit,tuck,miss, conveniently run with excellent precision and Lycra attachment.

Even no noise and high production performance on Single Jersey Circular Knitting Machine.

Through changing use different codes of Cams and needles, various kinds of fabrics in different tension and quality can be produced perfectly on Single Jersey Circular Knitting Machine

·Single Jersey Circular Knitting Machine can be changed to Terry jersey knitting machine and three thread fleece circular knitting machines.

SCOPE

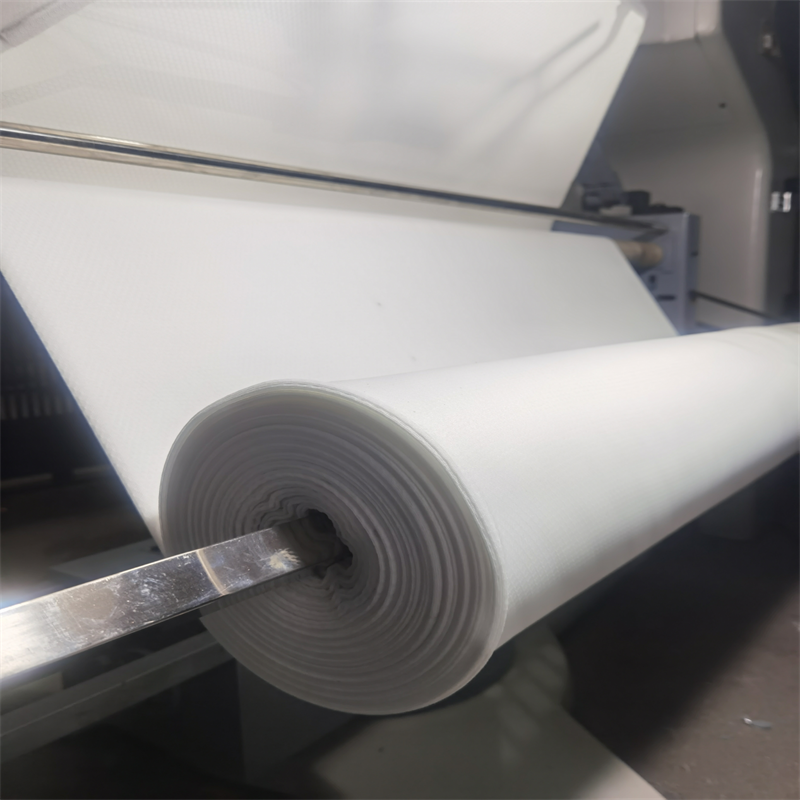

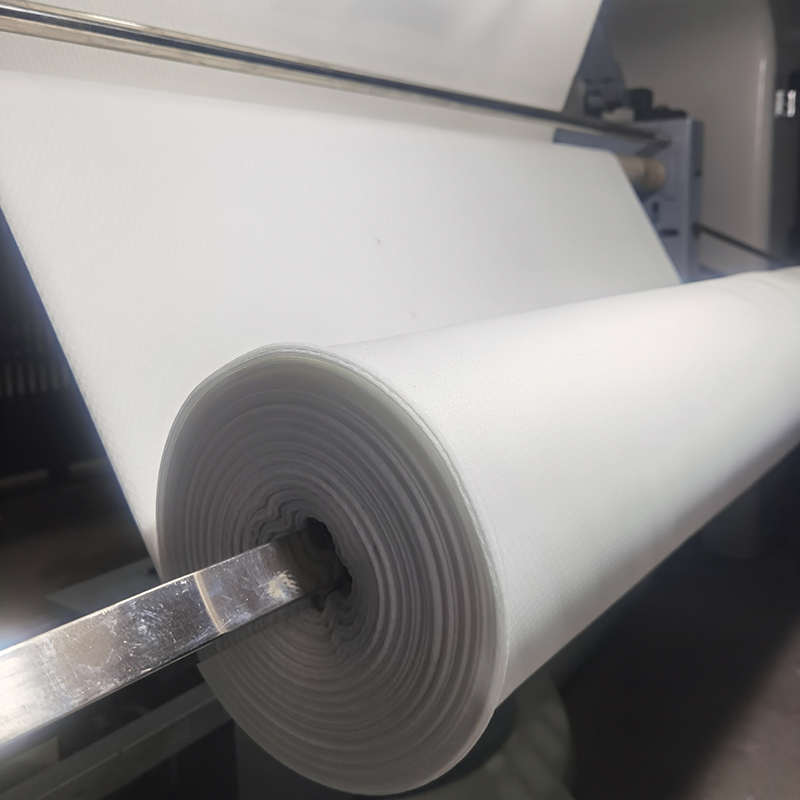

Sweat shirt, night clothes, Vest, T-shirt, Polo shirts, functional sportswear and underwear.

SCOPE

cotton, synthetic fiber, silk, artificial wool, mesh or elastic cloth,silk, blend, polyester viscose and synthetic fibers, etc.

DETAILS

Single Jersey Circular Knitting Machine use 4 track cams sealed solution of knit, tuck and miss cams. Single Jersey Circular Knitting Machine can be adopted with single tubular frame and open width frame.

Different size and weight of fabric can be produce in piece of cake and effectively by the high accuracy central stitch system.

A With special technical design, the yarn feeder leads to more precise choice of Lycra. With an ergonomic design, yarn is more easier to monitor by extra middle feeding yarn transfer ring,also make the operation more convenient; meanwhile, even in the high speed of operation,the whole yarn feeding system is more stronger and easier to level up the production on Single Jersey Circular Knitting Machine

The attitude to put customer as god doesn’t make good reputation in Single Jersey Circular Knitting Machine , but with many useful and meaningful characters which leads the knitting area:

• The newest oil treatment frame can carry one open-with system,huge fabric weight, and also some equipment customer require.

• higher RPM and almost no noise is our proud can be realized in the our newest knitting frame.

• highly accuracy yarn guiding system design is useful for multi-yarn feeding. The feeding of Lycra and three-yarn.

• the damage of unpredictable stop of running can be avoid by excellent designed bearing and gear are with oil protection for quality fabric production

• lubricator gives more energy to Needle and gear are absolutely protecting from pollution of fabric.Accurate stitch adjustment are positioning in backside of cam boxes

• the special design of cam surface for providing longer lifetime of sinkers and needles.

• full of energy of anti-dust system provides a clean machine body and fabric .

• many different diameters of Single Jersey Circular Knitting Machine and gauge are customized.

• multiple options of POMS for whole factory arrangement and highly strict quality control Highlights

1.Dust Removing: anti dust system is equipped on the top and middle to clean the machine for better fabric. The middle is equipped a well method to remove dust, which makes Single Jersey Circular Knitting Machine more cleaner and reduce lost of yarn.

2.Lightening: to have a good environment for masters to observe the knitting progress for better production,equipped the well lightening spots in the right place of machine for human engineering. It only cost few electricity but with more light to make the operation more easily in a safe mode.

3.Single Jersey Circular Knitting Machine used AA quality iron to avoid malformation of frame of machine through long natural treatment to make sure the accuracy of machine under long time operation condition.

![[Copy] Double Jersey 4/6 Colors Stripe Circular Knitting Machine](https://cdn.globalso.com/eastinoknittingmachine/xacacac-2-300x300.jpg)