Tubular preforms are made on circular knitting machines, while flat or 3D preforms, including tubular knitting, can often be made on flat knitting machines.

Textile fabrication technologies for embedding electronic functions into

Fabric production: knitting

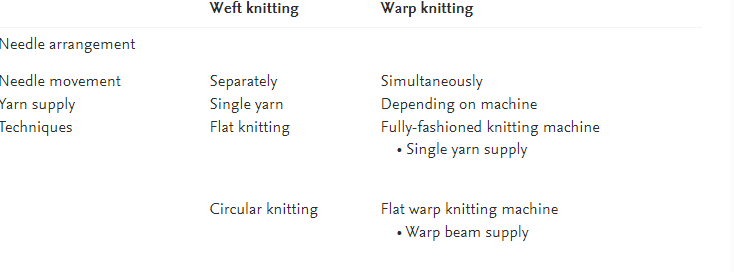

Circular weft knitting and warp knitting are the two primary textile processes included in the word knitwear (Spencer, 2001; Weber & Weber, 2008). (Table 1.1). It is the most typical process for creating textile materials after weaving. The qualities of knitted fabrics are entirely distinct from woven fabrics due to the interlooped structure of the fabric. The movement of the needles during production and the method of yarn supply are the root causes of the difference between circular weft knitting and warp knitting. One fiber is all that is required to create the stitches when using the weft knitting technique. While the warp knitting needles are moved concurrently, the needles are moved independently. Therefore, the fiber material is required by all needles at the same time. Warp beams are used to supply the yarn because of this. Circular knit, Tubular knit warp knit, flat knit, and completely fashioned knit fabrics are the most significant knitwear fabrics.

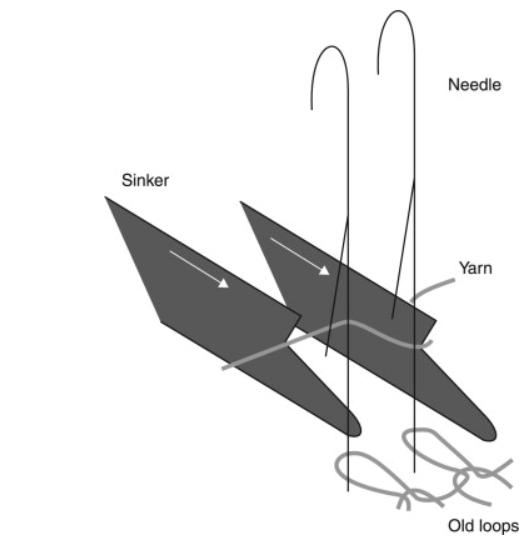

Loops are intertwined row after row to form the structure of knitted fabrics. The creation of a fresh loop using the provided yarn is the responsibility of the needle hook. The previous loop slips down the needle as the needle moves upward to capture the yarn and create a new loop (Fig. 1.2). The needle begins to open as a result of this. Now that the needle hook is open, the yarn can be captured. The old loop from the previous knitting circle is drawn through the freshly constructed loop. The needle closes during this motion. Now that the new loop is still attached to the needle hook, the previous loop can be released.

The sinker plays a crucial role in the creation of knitwear (Fig. 7.21). It is a thin metal plate that comes in a variety of shapes. The primary function of each sinker, which is positioned between two needles, is to aid in creating the loop. In addition, as the needle moves up and down to create the new loops, it keeps the loops that were created in the preceding circle down.

Post time: Feb-04-2023