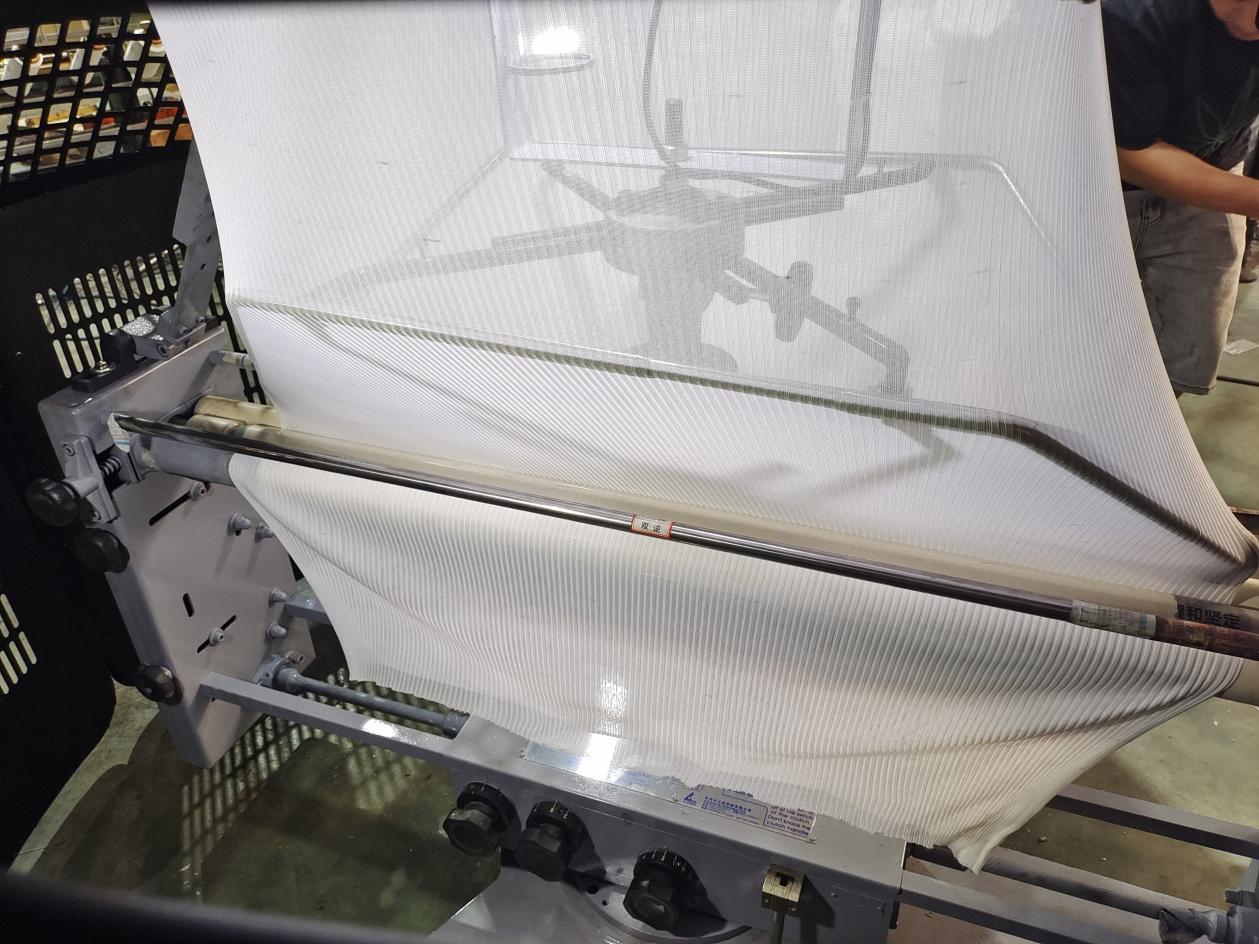

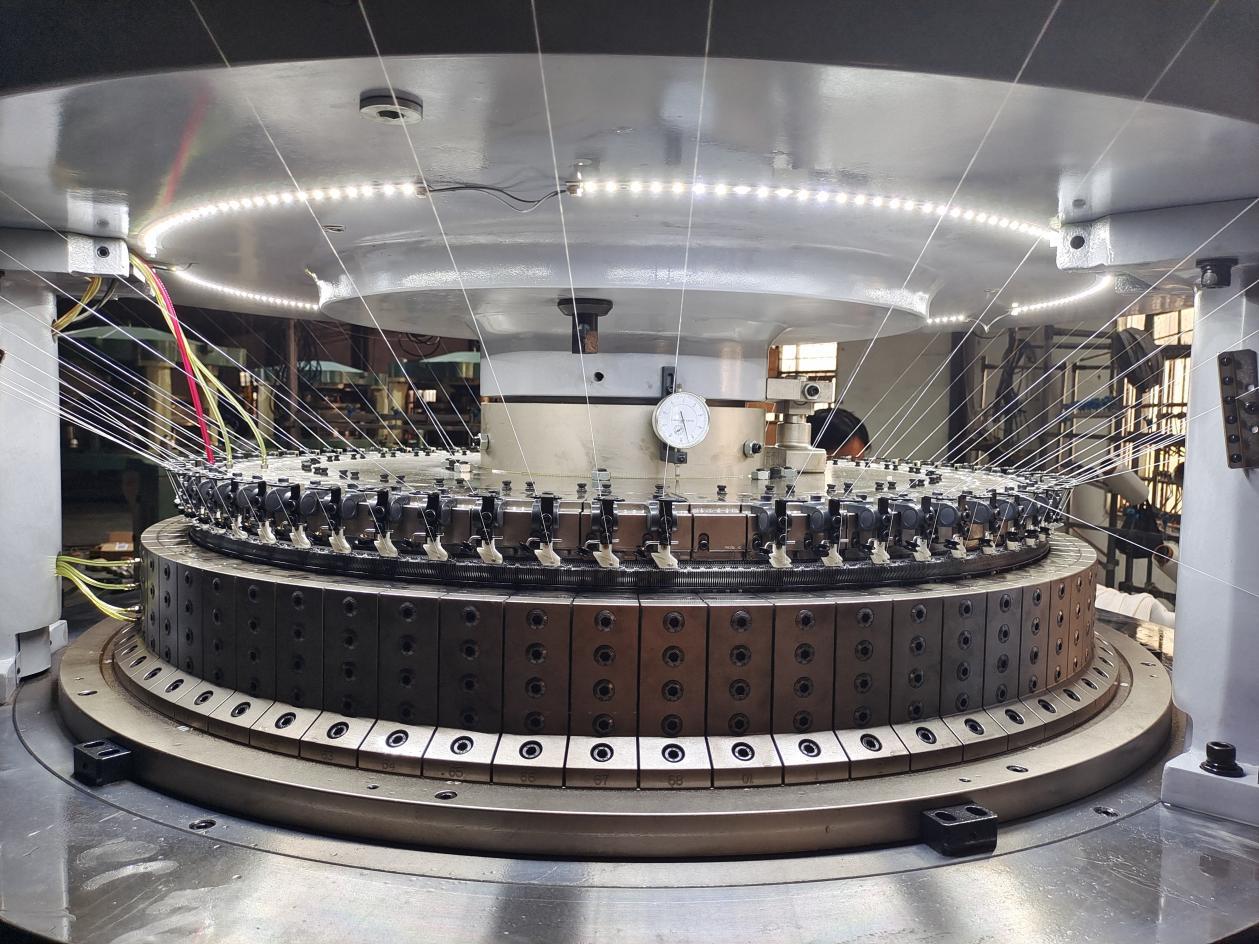

Double Jersey Interlock Spin-knit Circular Knitting Machine

FEATURES

The three operations of double jersey interlock Spin-knit Machine: spinning, cleaning and knitting.Spinit systems is special spin-knit technology of interlock Spin-knit Machine.It combines the processes of the circular knitting from spinning mill roving instead of yarn and the spinning.

Due to ring spinning, cleaning and rewinding are no longer required lowering production costs,the production process will be much shorter.interlock Spin-knit Machine leads to significantly well investment in machinery for customer.

Interlock Spin-knit Machines are similar of size to traditional machines, saves more space and energy with also producing less carbon dioxide and less waste. spinitsystems is enable to process a big variety of short-cut and staple fibre.

SCOPE&YARN

body size Double Jersey Rib cuff Circular Knitting Machine fits to knit cuff,twill ,Air layer ,Inter layer ,padded -bubble,stair cloth ,Double PK cloth,silk ,rib cloth and small jacquard cloth and so on .It's a double-side machine with the cams transform with super convenient.Easy protection items.Medial products.It is also can knit various special fabrics with special design.

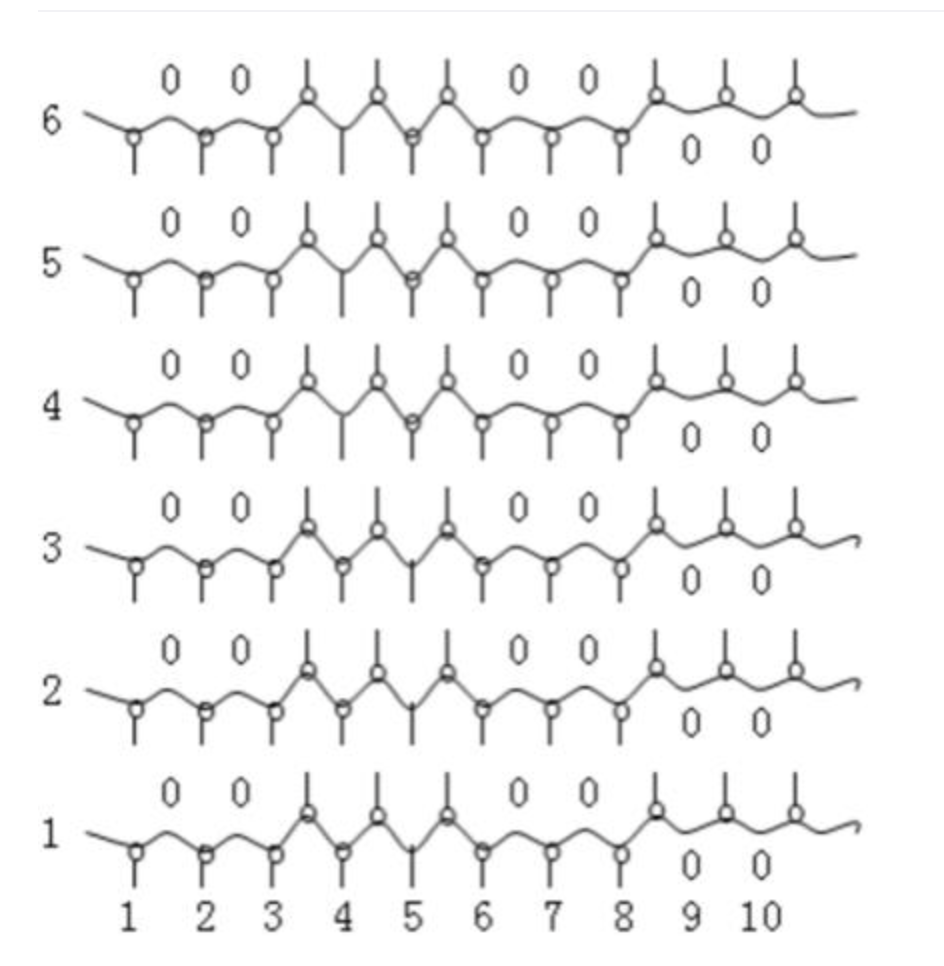

It is knitted by a cotton wool machine with some needles removed to form corresponding concave longitudinal stripes on the cotton wool cloth, hence the name. The raw materials used are cotton yarn, polypropylene yarn, acrylic yarn and so on. The amount of yarn used is less, and other characteristics are not much different from ordinary cotton wool. A variety of different needle extraction schemes can form concave stripes with different distribution rules. In the needle drawing scheme shown in the figure below, no needles are inserted into the 3, 5, 8, and 9 needle slots of the upper dial (also called drawing needles), and no coils are stitched in these positions, only floating lines, showing different widths and widths. Concave stripes.

Products of interlock Spin-knit Machine are widely used as cotton sweaters, pants, sweatshirts, pants and various outerwear and other fabrics.

DETAILS

This three-in-one concept, Using the so-called false twist spinning process, roving is converted directly into high-quality knitwear. The benefits of the interlock Spin-knit Machine include softness and a slight sheen. There are also the pattern options that the Fancy module offers. It enables the Spin-knit to vary the fineness of yarn during the production process and create entirely new patterns.

The technology also scores points with a significant reduction in process time due to the combination of the three process steps spinning, cleaning and knitting of interlock Spin-knit Machine

MARKET

interlock Spin-knit Machine will show a marketable and fully functional model, which it will bring to market.

That makes the production process much shorter because ring spinning, cleaning and rewinding are no longer required lowering production costs. For the customer this leads to significantly lower investment in machinery.

Industry professionals showed interest in the new approach at the 2015 ITMA that took place in Milan. We believes that the technology of interlock Spin-knit Machine has great opportunities for in China and a number of neighbouring countries.

Machine is mainly in highly developed textile markets. Where wage and manufacturing costs are high, our customers are constantly on the lookout for innovations. We have to offer something special, something that others don’t yet have. With machine and the characteristic fabric that it produces the customer is definitely a step ahead of the rest

What kind of fabric is weft knitted rib fabric?

Weft-knitted rib fabrics are formed by rib weave and are produced on double-sided weft knitting machines. The elasticity and extensibility of weft-knitted rib fabrics, the most commonly used knitted fabrics side by side with cotton wool.

The ribbed fabrics used for underwear are mainly cotton yarn, cotton/polyester yarn, cotton/acrylic yarn, etc., weaving 1+1 rib, 2+2 drawing rib and other drawing needle rib fabrics with different thicknesses on the surface. The vertical strip effect makes the appearance of the fabric changeable. It is used to sew undershirts, vests, autumn clothes, long pants, etc. Moisture absorption, breath ability, very good elasticity, comfortable to wear.

Use cotton yarn, cotton/polyester blended yarn, or interwoven with spandex yarn, 1+1 rib or 2+2 rib, etc. with tight weaving and superior elasticity, the fabric is soft, close-fitting, thick, warm, good air permeability, general, Exercise clothes, sweatshirts and pants, casual wear, etc.

Rib fabrics have excellent elasticity and low hemming properties. When the coils are broken, they can only be detached in the reverse knitting direction, so they are also often used for production.

What is knitted rib fabric? Classification and difference of knitted rib?

Rib knitted fabrics are knitted fabrics in which a single yarn forms wales on the front and back in turn. Rib knitted fabrics have the detach ability, hemming and extensibility of plain weave fabrics, but also have greater elasticity. Commonly used in the collar and cuffs of T-shirts, it has a good body-closing effect and has great elasticity.

Rib is the basic structure of double-sided circular knitting fabric, which is formed by the configuration of the front coil wale and the reverse coil wale in a certain proportion. Common ones are 1+1 rib (flat rib), 2+2 rib, and spandex rib. In terms of material composition, it is mainly composed of animal fibers, plant fibers and chemical fibers. The most commonly used material is made of 100% acrylic worsted. It is very suitable for cuffs, hem and so on for knitting winter clothes. mercerized cotton (plant fiber), low elastic silk (chemical fiber), high elastic silk (chemical fiber), artificial wool (chemical fiber), etc. There are two general types of rib: one is flat knitting rib; the other is circular knitting rib. Flat knitting rib can be divided into two categories: large computer flat knitting rib and general flat knitting rib. Large computerized flat knitting machines are expensive and can weave patterns, while general computerized flat knitting machines do not have this function. Most of the flat knitting rib on the market now is woven by general flat knitting machine.