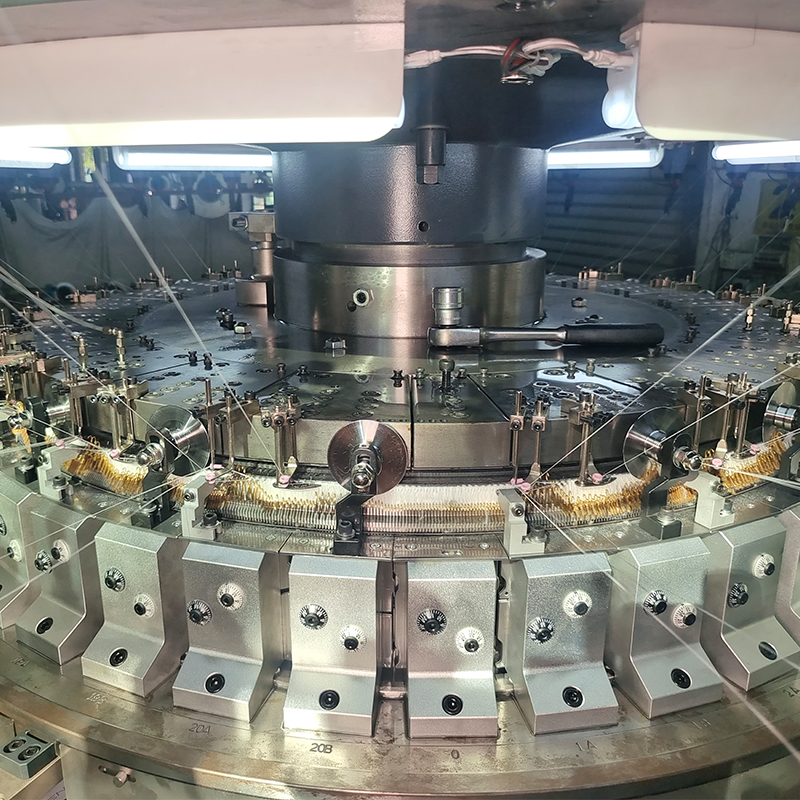

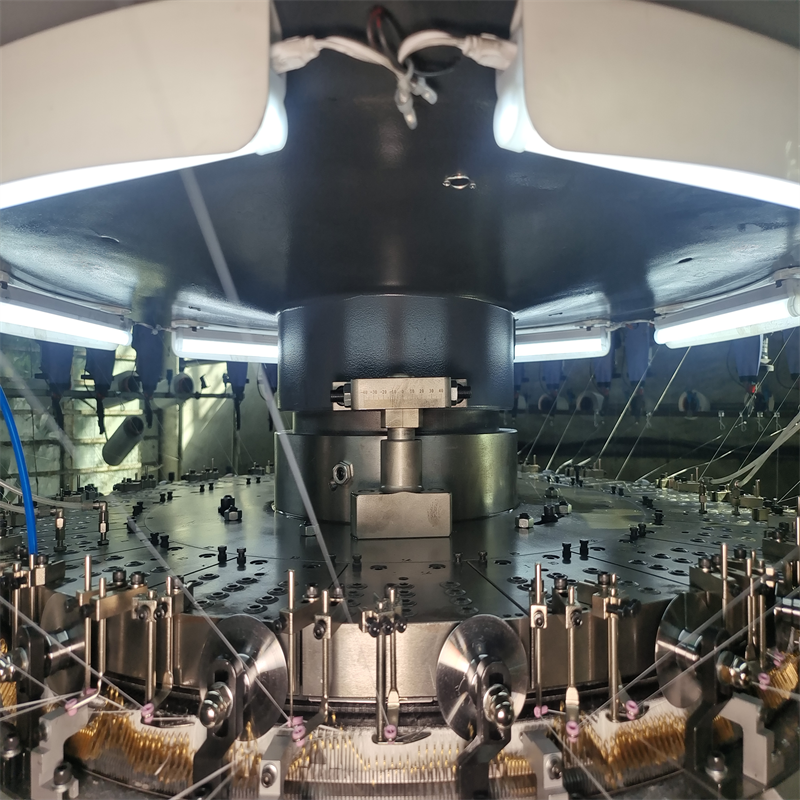

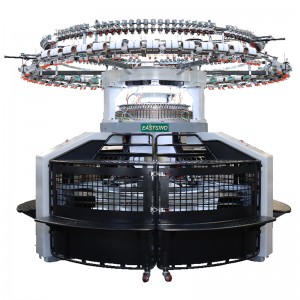

Double Jersey Computerized Jacquard Loop Cut Circular Knitting Machine

Features

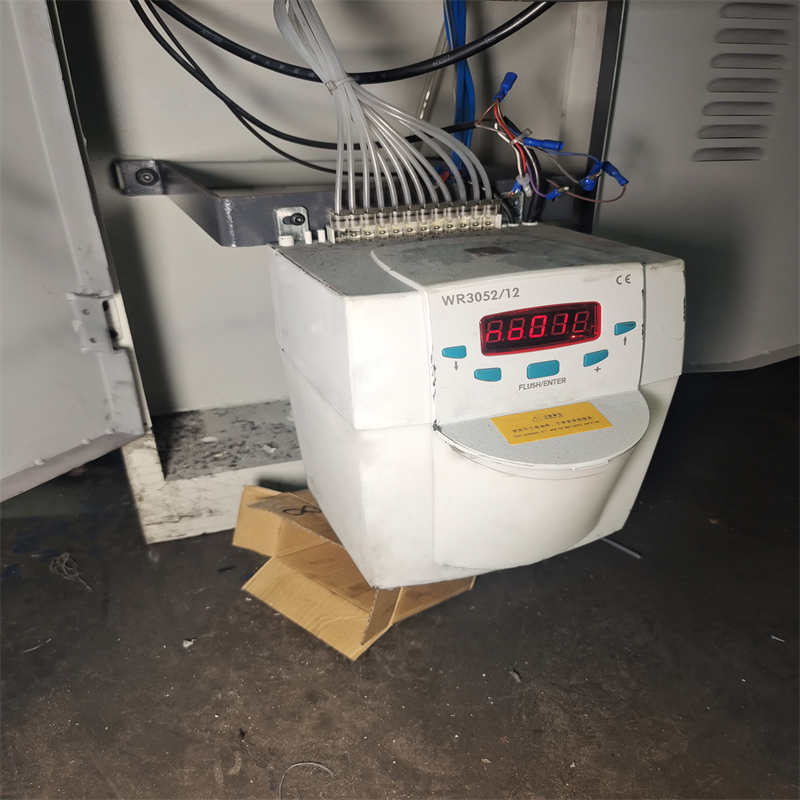

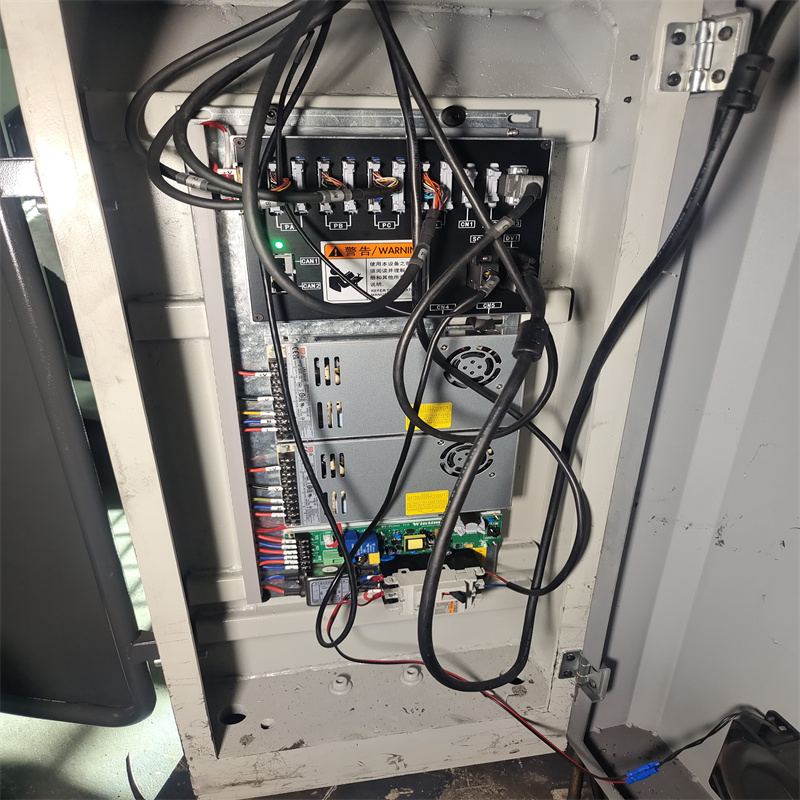

Computerized charge system is the main dish of Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine serve.Patterns design are storage in a simple USB memory card are ready to cooperate with computerized needle choosing system.

With the function of memory record for stop Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine,pattern plate is easy to use.with the stable and reliable synchronous transmission,a good basis is built up for loop cutting,pattern writing and speeding up the operation.

Multiple colors and patterns can be design and realized in your hand with Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine.Fabric are popularly useful in a wider dimension such as weaving upscale cloth,bedclothes,craft toys ,car mat ,house carpet ,etc.

SCOPE

Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine is widely used in the weaving of blankets, square carpets, car carpets, bathroom and bathroom blankets, decorative craft blankets, sofa beds, curtains, pilgrimage blankets, jacquard blankets, etc.

Weaving is suitable for three-dimensional, flat landscapes, flowers, characters, animals, characters and arbitrary patterns of clothing fabrics, bedding, craft accessories, toys, carpets, tapestries, so that you can maintain a leading position in fabric innovation.

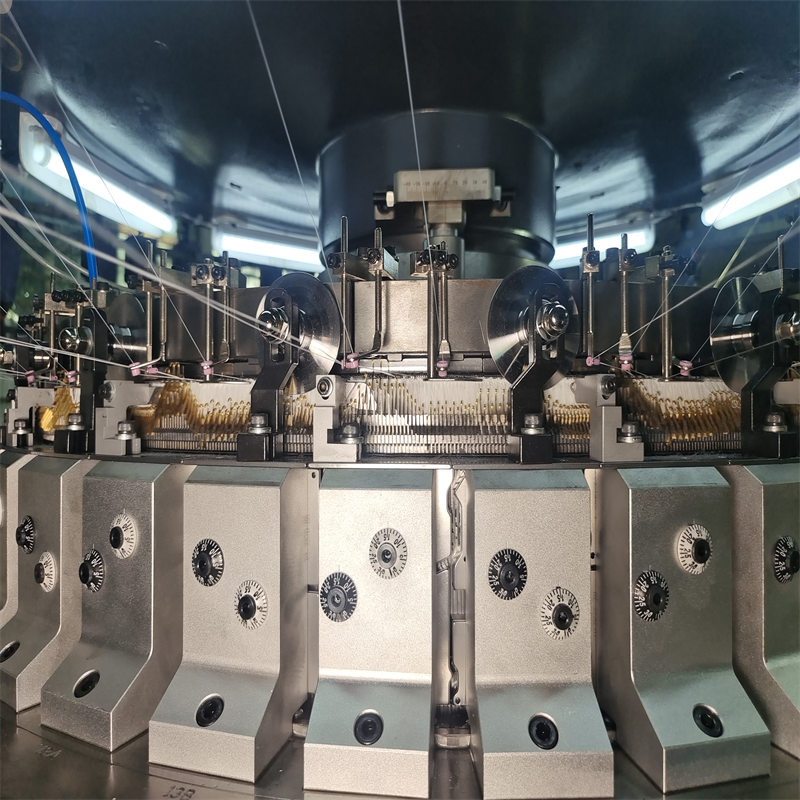

Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine adopts a double-sided model structure, which is elegant and beautiful in appearance, easy to operate and has high production efficiency.

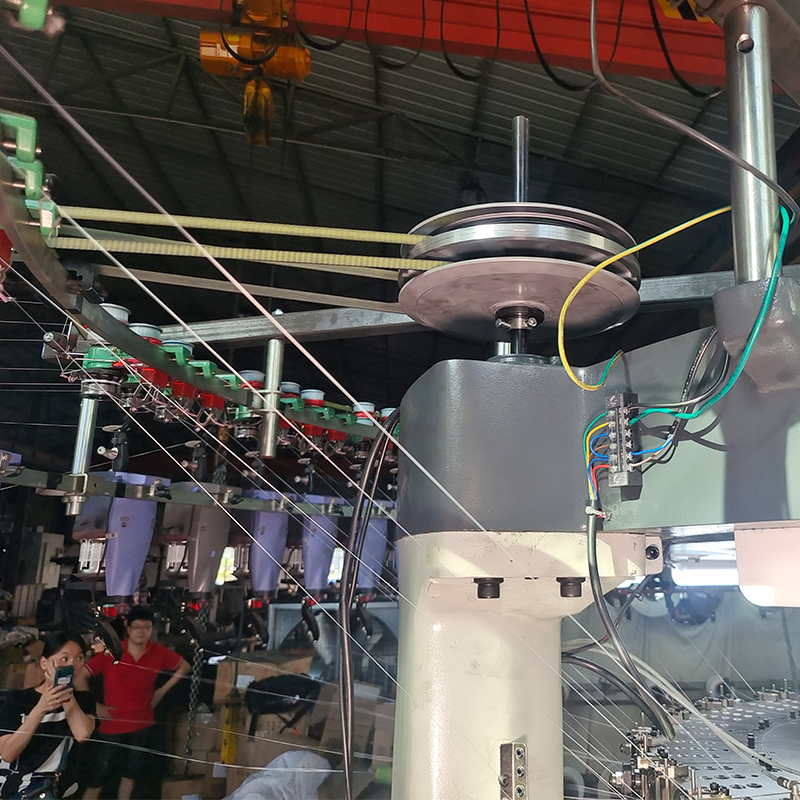

YARN

Acrylic, polypropylene, nylon, cotton, wool, chenille, rayon, polyester bright silk, etc.

DETAILS

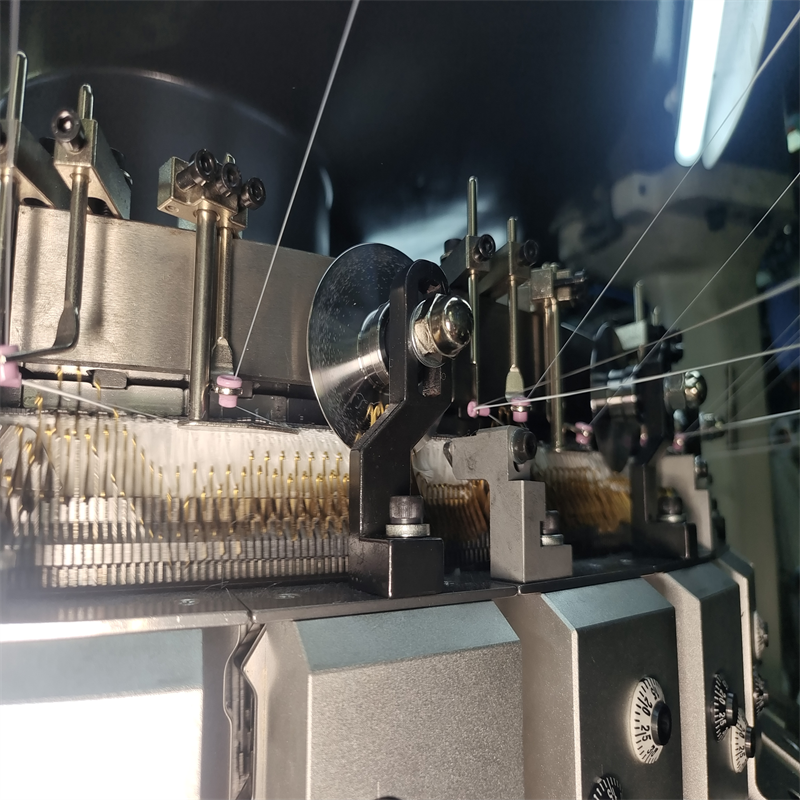

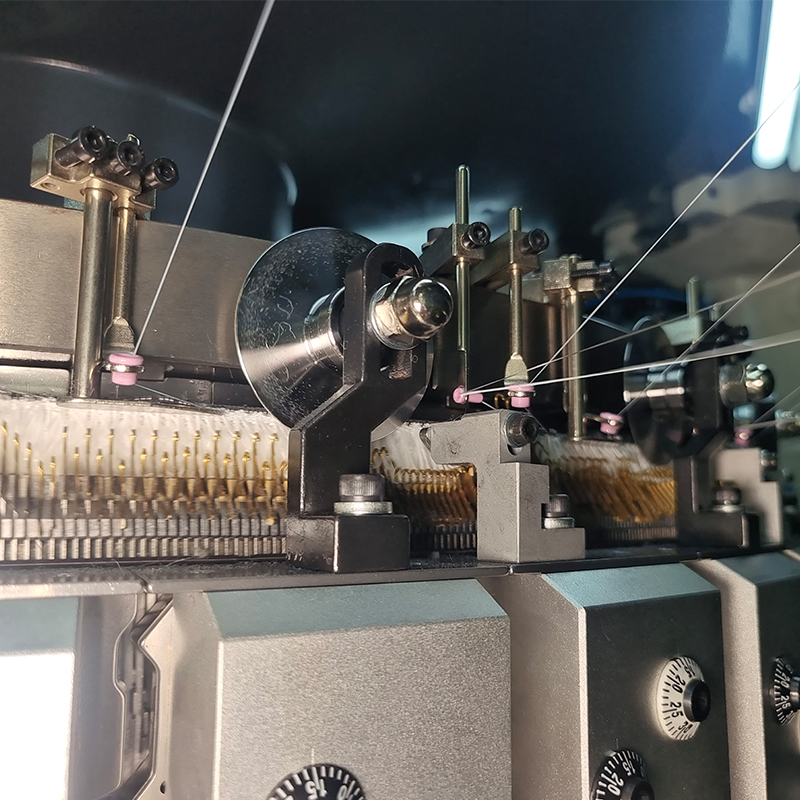

Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine is a AA quality computerized jacquard loop cut circular knitting machine preciously created by our factory using the newest circular knitting mechanical technology. Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine can perform plane cutting pile, bump cutting pile, yarn-dyed cutting pile according to the needs

Compared with traditional tufting machines, this series of models has the following advantages:

1.The traditional tufting machine needs a layer of base fabric, but this series of models is a weft knitting machine, which is naturally woven and does not require a base fabric, so it saves lots of costs.

2.This series of Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine has a high fabric production, each operator can take care of 5-8 units, and the output of each unit (24 hours) is about 300 square meters, while the traditional tufting machine can only produce more than 10 units per day (8 hours). Therefore, it can greatly save labor, improve productivity and increase economic benefits to get higher profit.

3.Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine is one of hot sale products of our factory, the width can reach 2 meters, and the maximum daily output can reach 300 square meters. And one machine basically has the function of high and low secant line in full secant, full loop pile, low loop high cut, high and low loop pile, and can be widely used in square carpets, car carpets, bathroom mats and other household mats. and production of commercial pads.

4.This series of Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine can make carpets with different styles such as plane cutting, yarn-dyed loop pile, high and low loop pile, low loop high cut, high loop high cut, etc. The pattern can be designed by yourself and designed by computer.

5.Double Jersey computerized Jacquard Loop Cut Circular Knitting Machine has the characteristics of small footprint, high efficiency, low energy consumption, no tail yarn waste, etc.