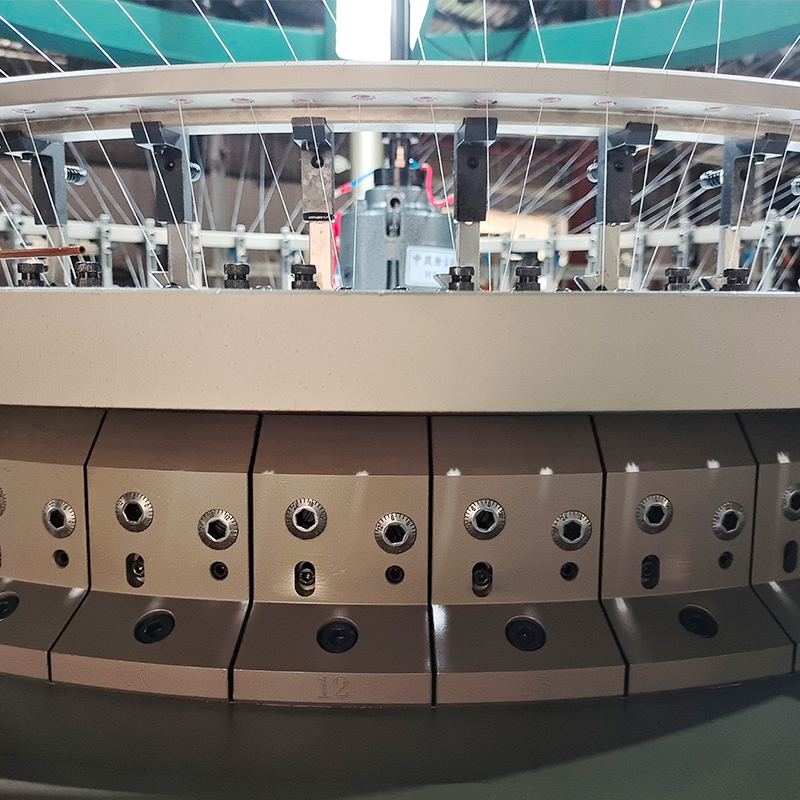

Single Jersey Terry Towel Circular Knitting Machine

Specification of Machine

The double sinker design of Single Jersey Terry Towel Circular Knitting Machine can weave loops with front and back wrapping structures, providing users with sinkers with different hair lengths.

Its computer control system of Single Jersey Terry Towel Circular Knitting Machine is powerful enough to automatically survey and control every operating parameter including spraying oil regularly, dust removing, needle breakage detection, automatic stop when there is a broken hole on the Fabric or the output reaches the set value and so forth.

Single Jersey Terry Towel Circular Knitting Machine through the inner and outer sinkers, it is possible to weave special fabrics that are hairless and have loops on one side of the inner and outer sides.

Fabric Sample

Single Jersey Terry Towel Circular Knitting Machine can be used to weave terry fabrics, including single-sided terry and double-sided terry fabrics, and finished fabrics. Suitable for household clothing, supplies and cleaning supplies such as bathrobes, bath towels, towels, pajamas, towel blankets, etc.

Our CompanyInstallment and Debugging

Our quality--Product quality is our core competitiveness.We will carry out a through inspection of all the circular knitting machines and it's parts before delivery.so as to guarantee high product quality,if there is any quality problem under warranty,we will replace related parts for free.

Package

First we usually wipe the machine with anti-rust oil , then add plastic wrap to protect the circular knitting machine of cylinder;Second, we will add custom paper skin on the machine foot to protect the machine; Third, we will add a vacuum bag to the machine, and finally the product will be packed in wooden pallets or wooden boxes.

RFQ

Q:How long does your mold development take?

A:It usually takes 15-20 days. If the model is special, we need a week to prepare and one to two weeks to arrange the casting production.

Q: Does your company charge mold fees? how many? Is it possible to return it? How to return?

A:If the mold can be used by us on other customers' machines, it will be regarded as our company's research and development expenses and will not be charged by customers.

If the mold is developed by the customer and we are not allowed to use it on other customers' machines, then a special mold fee will be charged.

Q:How long does your company's normal product delivery time take?

A: The annual output of our company is about 1800 units, and the normal order delivery time is within 5 weeks.