For businesses in the textile, fashion, and home goods industries, investing in a knitting machine can significantly boost production efficiency and expand design possibilities. The demand for high-quality, innovative fabrics is rising, and knitting machines play a key role in meeting this demand. However, selecting the right knitting machine and understanding how to use it efficiently is essential for businesses to stay competitive. In this comprehensive guide, we’ll explore how knitting machines work, the different types available, and provide a step-by-step process for effectively using one. We’ll also cover the key factors to consider when purchasing a knitting machine for your business.

What is a Knitting Machine and How Does It Work?

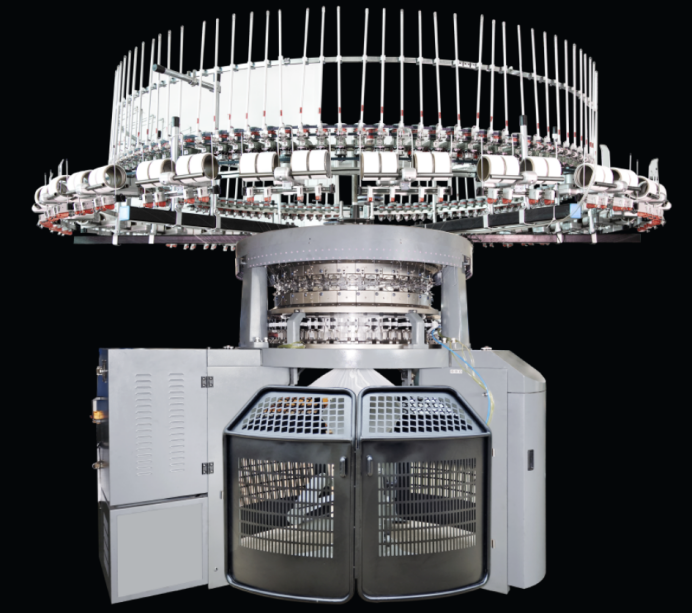

A knitting machine is a mechanical or electronic device designed to automate the process of creating knitted fabrics. By interlocking yarns using needles and hooks, knitting machines produce fabric much faster than hand knitting. These machines are essential in industries like apparel, home textiles, and automotive manufacturing, producing everything from basic garments to intricate knitting patterns.

Types of Knitting Machines

There are several types of knitting machines, each suited for different needs: Flat Knitting Machines : Used to create flat fabrics, ideal for garments like sweaters and scarves. These machines are versatile and can produce both simple and complex designs.

: Designed to create tubular fabrics, circular knitting machines are best suited for items like socks, t-shirts, and seamless garments.

Jacquard Knitting Machines : Equipped to create detailed patterns and multi-color designs, Jacquard machines are essential for businesses focused on high-end or custom fabrics.

By understanding these different types of knitting machines, you can choose the right one that aligns with your product goals.

How to Use a Knitting Machine: Step-by-Step Guide

Operating a knitting machine can be a straightforward process when you know the steps. Here's how to get started:

Setting Up the Knitting Machine

1. Threading the Yarn : Start by properly threading the yarn through the yarn feeder, tension devices, and needle hooks. Ensure there are no tangles and that the yarn is positioned correctly to avoid interruptions during the knitting process.

2. Adjusting the Settings : Before starting, adjust the machine settings to suit the fabric you're making. For instance, set the stitch size, tension, and speed based on the yarn type and desired fabric outcome. Heavier yarns will need slower speeds and different tension settings compared to finer threads.

3. Ensuring Proper Tension : Yarn tension directly impacts the quality of your fabric. Too loose, and the fabric will be uneven; too tight, and the yarn may break. Ensure the tension is just right to create a smooth, consistent product.

Operating the Knitting Machine

1.Select the Pattern : Modern knitting machines typically allow you to select from predefined knitting patterns. Depending on your machine model, you can even input custom designs if you’re aiming for a unique fabric or garment.

2.Start the Knitting Process : Once everything is set up, start the machine. The yarn should be fed smoothly into the needles, and the knitting will begin. During the initial rows, monitor closely for any issues like incorrect tension or yarn snags.

3.Regular Monitoring : As the knitting process continues, periodically inspect the fabric being produced to ensure everything is running smoothly. Early detection of problems like uneven stitches can save time and reduce waste.

To ensure your knitting machine runs at optimal capacity, regular maintenance is crucial. Clean the machine frequently, lubricate moving parts, and inspect for any worn-out components or loose needles. Regular maintenance extends the machine’s lifespan and prevents production delays caused by unexpected malfunctions.

Key Considerations When Choosing a Knitting Machine for Your Business

When selecting a knitting machine, consider these key factors to ensure you choose the right one for your business needs.

1. Production Volume

If your business requires high-volume production, opt for industrial-grade knitting machines that can handle continuous operation. Circular knitting machines, for example, are designed for high-speed production of garments like socks and t-shirts, while flat knitting machines are better for smaller runs or more intricate designs.

2. Fabric Type and Design Flexibility

Different machines are better suited for different fabric types. If you need flexibility in your designs—such as multi-color or textured patterns—a Jacquard knitting machine is an ideal choice. Conversely, if you’re producing standard fabrics or garments, a simpler flat or circular knitting machine will suffice.

3. Cost vs. Performance

While high-quality knitting machines can be costly, they often come with advanced features that can increase production efficiency and reduce errors. Balancing the upfront cost with the potential increase in output and consistency is key. Remember that investing in a more advanced machine can help reduce long-term operational costs by improving efficiency.

4. Automation and Ease of Use

Look for machines with automated features, such as automatic tension control, pattern programming, and error detection. These features will help streamline your production process, reduce human error, and minimize downtime. Additionally, machines with user-friendly interfaces make it easier for operators to get up to speed quickly, reducing training costs and improving overall efficiency.

Popular Knitting Machines for B2B Buyers

Model X: High-Efficiency Circular Knitting Machine

Features : Designed for mass production of seamless garments like t-shirts, socks, and leggings. Known for high-speed knitting and minimal downtime.

Best For : High-volume manufacturers that require consistent, high-quality results in a short amount of time.

Model Y: Versatile Flat Knitting Machine

Features : Offers customizable knitting patterns and a broad range of stitch options. Ideal for small to medium-sized businesses that require flexibility in production.

Best For : Custom garment manufacturers and those specializing in home textiles or intricate knitted designs.

Model Z: Advanced Jacquard Knitting Machine

Features : Capable of creating complex designs and multi-color patterns, this machine is perfect for businesses that need high-end, customized fabrics.

Best For : Designers and businesses focusing on bespoke fabrics and fashion-forward designs.

Where to Purchase Knitting Machines

When purchasing a knitting machine, it’s important to choose a reliable supplier. Look for companies that offer high-quality machines backed by warranties and excellent customer support. Many suppliers also provide after-sales services, including installation and training, which can be beneficial for businesses new to using knitting machines. If you’re looking for specific models, be sure to check out their product pages for detailed specifications.

Knowing how to use a knitting machine effectively is essential for businesses aiming to streamline their production process and meet growing market demands for high-quality fabrics. Whether you're operating a large-scale manufacturing facility or a boutique business focusing on custom designs, understanding how knitting machines work and selecting the right machine is key to your success. By considering factors like production volume, fabric type, cost, and ease of use, you can make a well-informed decision that will enhance your operations and product offerings.

Ready to improve your production capabilities? Contact us today for personalized recommendations or request a quote for knitting machines tailored to your business needs. Let us help you streamline your manufacturing process and elevate your product quality!

Post time: May-15-2025