14-28 Inch Mid Gauge Circular Knitting Machine

Features

With humanized and the right beauty of streamlined design,Mid Gauge Circular Knitting Machine height is suitable for operator to do the duty well, we said easy operation. It is convenient to change the Cams,Needles and other parts with our professional guidance. Its benefit is to save the error time to provide efficiency production.

With cylinder using air craft special aluminum alloy material, more light weight ready for high speed and excellently save cooling time.Also the appearance of Mid Gauge Circular Knitting Machine is over high-grade

With special hanging type yarn feeding system design on Mid Gauge Circular Knitting Machine, the yarn guide and Lycra attachment is in a more stable situation.It is efficient to provide high speed of machine production and keep continuous good quality of fabric.

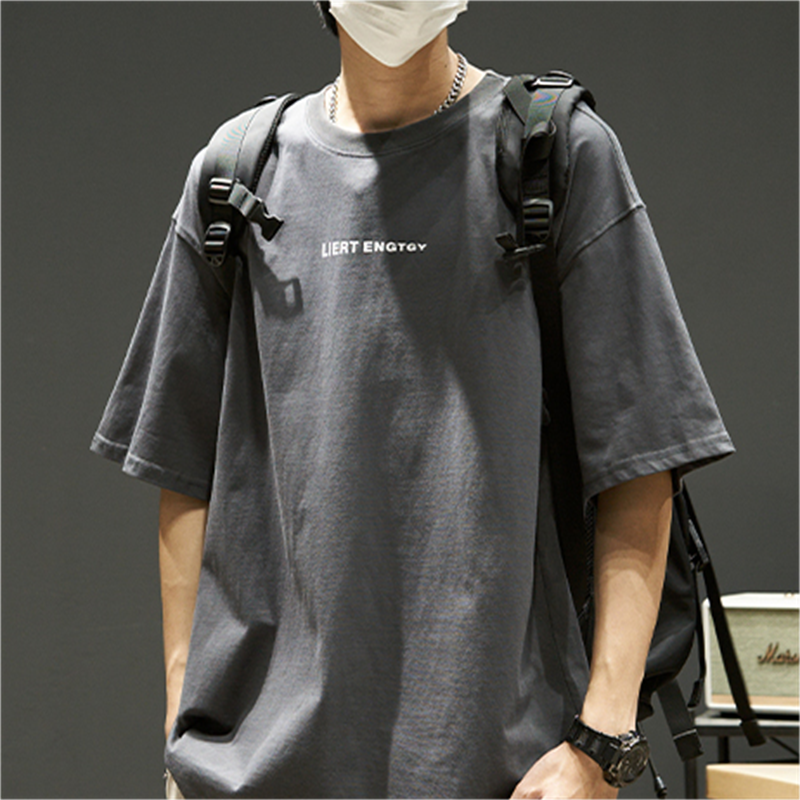

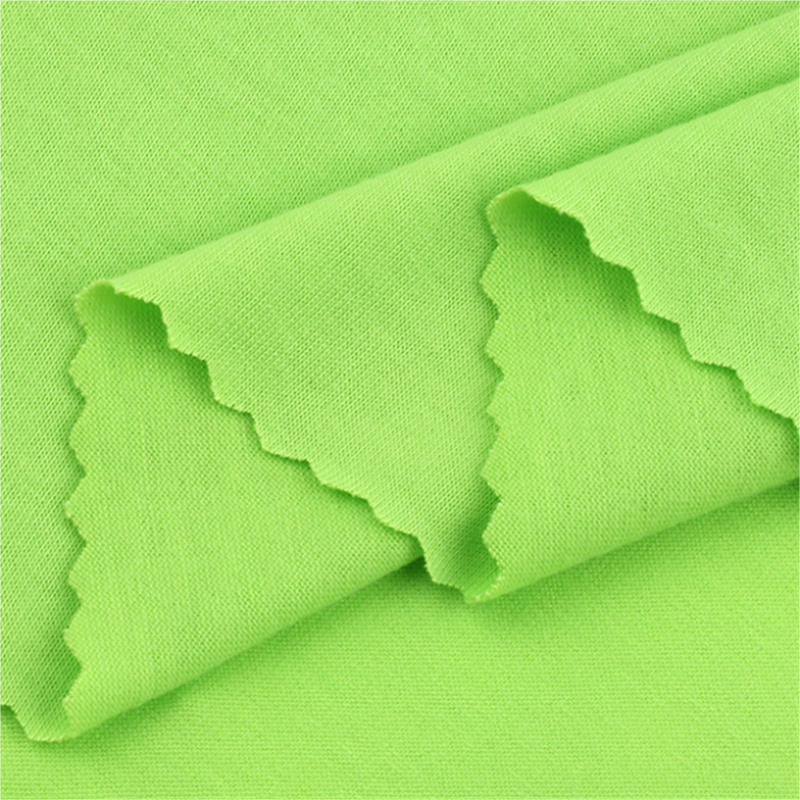

Fabric sample

Mid Gauge Circular Knitting Machine weaving materials widely used cotton yarn, polyester, TC, by changing the cams arrangement can knit different tissues of single jersey or double jersey fabric; Such as spandex single jersey, polyester / cotton single-sided single fleece cloth, color cloth, but also can produce single, mesh cloth, etc.

DETAILS

There are many spindles on the warp creel of Mid Gauge Circular Knitting Machine. According to the width of the woven fabric and the width of the flat yarn, a specified number of warp yarns are used. Before the warp yarn enters Mid Gauge Circular Knitting Machine, the warp yarn is crossed by the brown frame of the warp yarn, and the weft yarn shuttle is crossed In the opening, the warp is passed through the warp in a circular motion, and it is woven into a tube fabric. Mid Gauge Circular Knitting Machine has several shuttles, and several weft yarns are woven at the same time.

In the early days, domestic circular looms were all imported circular looms, but in the 1990s, this situation gradually changed. For the first time, circular looms with independent intellectual property rights were born in my country, and in 1991, In 1993 and 1997, the second, third and fourth generation circular looms were successively launched. In August 2000, the world's first ten-shuttle super circular loom, SPCL-10, was successfully developed, integrating a number of advanced technologies. /6000, the fifth-generation circular loom, and then in January 2005, the world's first twelve-shuttle super plastic circular loom was born and delivered to users. Four years later, in November 2009, the world's giant sixteen-shuttle plastic circular loom SPCL-16/10000 was ordered. So far, the level of Mid Gauge Circular Knitting Machine in my country has steadily ranked the world's leading level.

1. Weft sensor: Clean the detector cover regularly (once every four hours). When Mid Gauge Circular Knitting Machine is running, make sure that the white light is always on. The detector is designed according to the principle of infrared rays. The dazzling light will affect the performance of the sensor. Try to stay near the machine as much as possible. Use only daylight bobbins, if the surface of the spindle is shiny, the detector may not work accurately, avoid using aluminum bobbins or black bobbins, black yarn will make the detector inoperable.

2. Weft breakage sensor: In the normal operation of the circular loom, when the weft thread is broken due to external force, the sensor detects the signal and transmits it to the controller to control the circular loom to stop. If the weft thread is broken, the machine cannot automatically stop: Jog the machine, make the yarn guide tube of one of the shuttles run below the sensor, manually and quickly break the weft thread, so that the steel ball enters the detection range of the sensor. If the red indicator light of the sensor is not on, adjust the sensor position until the red indicator light is on. or replace the sensor.

3. Main speed detection sensor: During the normal operation of Mid Gauge Circular Knitting Machine, if the range of the boost frequency conversion frequency is large, it may be that the sensor has missed the detection of the rotation of the main engine due to vibration. At this time, it is necessary to adjust the position of the sensor so that the head of the sensor is aligned with the toothed plate. , and then observe to increase the frequency conversion frequency. If it beats within a small range, it is enough. If the effect cannot be achieved after several adjustments, replace the sensor.

4. Lift the detection sensor: If the man-machine interface cannot accurately record the output,check whether the wiring is correct. If the wiring is correct, adjust the position of the sensor, run the machine, and observe whether the indicator light is flashing. If it does not flash, consider replacing the sensor.Mid Gauge Circular Knitting Machine