Whether you're a hobbyist, small batch designer, or textile start up, mastering a circular knitting machine is your ticket to fast, seamless fabric production. This guide walks you through using one step by step—perfect for both beginners and pros upgrading their craft.

Here’s what you’ll cover:

Understand how these machines work

Choose the right model, gauge, and yarn

Set up and thread your machine

Run a test swatch

Troubleshoot common issues

Maintain your machine

Scale up your knitting workflow

1. Understanding Circular Knitting Machines

What are they?

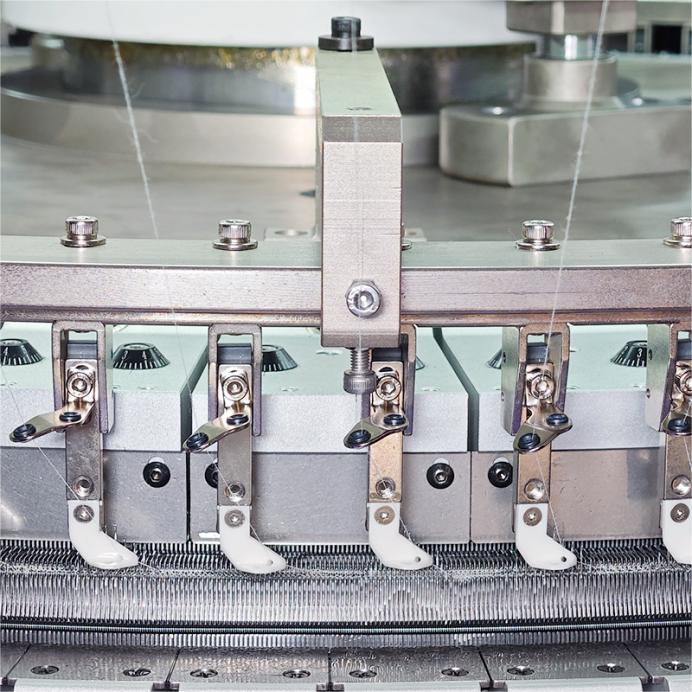

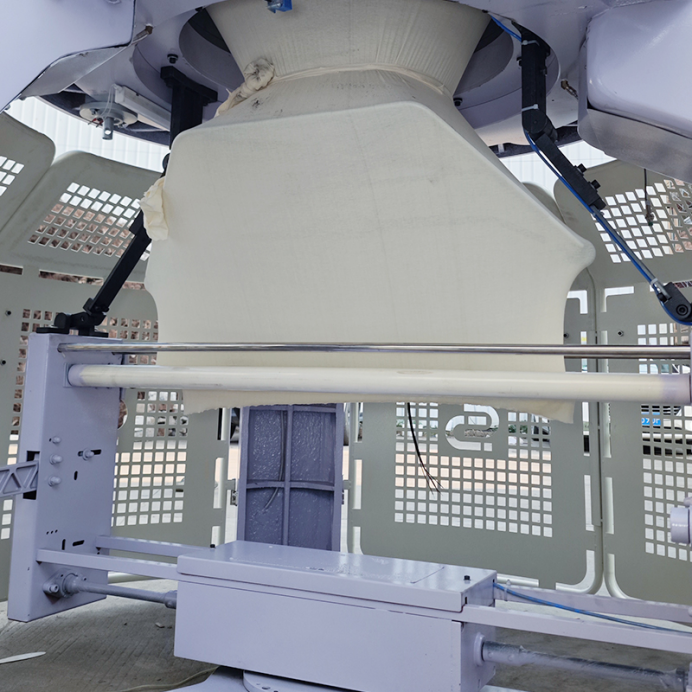

A circular knitting machine uses a rotating needle cylinder to knit seamless tubes of fabric. You can produce anything from fitted beanies to large tubular panels. Unlike flatbed machines, circular units are faster and ideal for cylindrical products.

Why use one?

Efficiency: Knits continuous fabric up to 1,200 RPM

Consistency: Uniform stitch tension and structure

Versatility: Supports ribs, fleece, jacquard, and mesh

Scalability: Run multiple styles with minimal rethreading

LSI Keywords: knitting technology, fabric machine, textile machinery

2. Choosing the Right Machine, Gauge & Yarn

Gauge (Needles per Inch)

E18–E24: Everyday knit fabrics

E28–E32: Fine-gauge tees, gloves, ski hats

E10–E14: Chunky hats, upholstery fabric

Diameter

7–9 inches: Common for adult beanies

10–12 inches: Large hats, small scarves

>12 inches: Tubing, industrial usage

Yarn Selection

Fiber type: Acrylic, wool, or polyester

Weight: Worsted for structure, bulky for insulation

Care: Machine-friendly blends for easy maintenance

3. Setting Up and Threading Your Machine

Follow these steps for foolproof setup:

A. Assemble and Level

Ensure sturdy table and machine bolted to work surface

Align cylinder level; misalignment can cause tension issues

B. Thread Yarn

Route yarn from cone → tension disk → eyelet

Insert into feeder; ensure no twists or tangles

Adjust feed tension until yarn feeds freely

C. Thread Feeder for Patterns

For stripes or colorwork: load additional yarns into secondary feeders

For rib: use two feeders and set gauge accordingly

D. Lubricate Moving Parts

Apply ISO VG22 or VG32 oil to cams and springs weekly

Clean lint and dust before reapplying lubricant

4. Creating a Test Swatch

Before launching into production:

Knit about 100 rows at medium speed (600-800 RPM)

Observe:

Stitch formation — any dropped loops?

Stretch & recovery — does it snap back?

Fabric width/length per row — check gauge

Adjust tension + RPM if:

Stitches look loose/tight

Yarn breaks or stretches under tension

Internal Link Tip: Read How to Troubleshoot Knitting Defects for fixes

5. Knitting Full Pieces

Once your swatch passes inspection:

Set desired row count for item length

Beanies: ~160–200 rows

Tubes/scarf blanks: 400+ rows

Start automated cycle

Monitor every 15–30 minutes for missed loops, yarn break, or tension drift

Stop and collect fabric once complete; cut and secure edge

6. Finishing and Crowning

Circular knit (https://www.eastinoknittingmachine.com/products/)items usually lack a top closure:

Use a band saw or hand cutter to open tube

Thread tail through crown stitches with yarn needle

Pull tight; secure with 3–4 small back stitches

Add trims like pom-poms, ear flaps, or labels at this stage

7. Maintenance & Troubleshooting

Daily

Clean yarn feed temp, tension disks, and take down units

Check for needle burrs or rough spots

Weekly

Oil cams, springs, and take-down rollers

Test RPM calibration

Monthly

Replace worn needles and sinkers

Realign cylinder if fabric shows narrowing

Fixing Common Issues

|

Problem |

Cause and Solution |

| Dropped stitches | Bent needles or incorrect tension |

| Yarn breakage | Sharp tip, too much RPM, poor-quality yarn |

| Uneven loops | Misthreaded feeder or cylinder misalignment |

| Fabric twist | Improper take-down tension or flawed roller |

8. Scaling and Efficiency

Interested in going pro?

A. Run Multiple Machines

Set up identical machines for different styles to minimize changeover.

B. Track Production Data

Keep records: RPM, row count, tension settings, swatch results. Monitor consistency across runs.

C. Part Inventory

Maintain spare parts on-hand—needles, sinkers, o-rings—to avoid downtime.

D. Train Staff or Operators

Ensure coverage in case of machine issues or staff availability gaps

9. Selling Your Knitted Items

Want to turn stitches into sales?

Branding: Sew in care labels (machine-washable), size tags

Online Listings: SEO-friendly titles like “Hand-knitted circular knit beanie”

Bundling: Offer sets—hats + scarves for $35–$50

Wholesale: Send to local shops or craft co-ops

Conclusion

Learning how to use a circular knitting machine(https://www.eastinoknittingmachine.com/products/) transforms ideas into tangible products. With the right gauge, yarn, and setup—plus disciplined maintenance—you’re ready to create professional-grade items at scale.

Post time: Jul-09-2025