At the upcoming Techtextil North America (May 6–8, 2025, Atlanta), German textile machinery giant Karl Mayer will unveil three high performance systems tailored for the North American market: the HKS 3 M ON triple bar high speed tricot machine, PROWARP® automatic sectional warping system, and WEFTTRONIC® II RS weft insertion raschel machine. Leveraging digitalization, energy efficiency, and multi material processing, these next gen solutions aim to serve the booming technical textiles and nearshore apparel manufacturing sectors while expanding KM’s local support and spare parts network in the Americas. ( karlmayer.com )

1. Techtextil NA as a Premier Innovation Platform

As the only U.S. trade fair covering the entire technical textiles and nonwovens supply chain, Techtextil NA will host Karl Mayer at Hall B’s German Pavilion . The booth will feature live demos via digital twin interfaces , video walkthroughs, and fabric samples, showcasing an integrated workflow from yarn preparation to finishing.

Mariano Amezcua , KM’s North America CEO, emphasized: “Face to face collaboration with clients is invaluable—especially as supply chains rapidly shift toward nearshoring.” ( karlmayer.com )

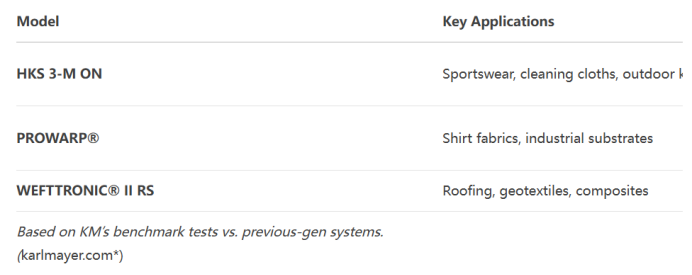

2. Three Flagship Machines at a Glance

3. Tech Breakthroughs vs. Industry Pain Points

✅ Plug and Play Digitalization

The HKS 3 M ON integrates KAMCOS 2 and k.ey cloud , enabling 48 hour MES connectivity for real time OEE, energy, and carbon tracking.

✅ Expanded Material Compatibility

PROWARP® handles PBT/elastane blends and UHMWPE via programmable tension control, eliminating yarn misalignment in sectional warping.

✅ Energy Saving Upgrades

WEFTTRONIC® II RS features EES (Energy Efficiency Solution) , cutting power use by 11% via adaptive servo drives.

✅ Ultra Width Precision

HKS 3 M ON’s carbon reinforced guide bars maintain 2,800 rpm at 280″ , with <2 mm edge to edge deviation .

4. Why North America?

Infrastructure Boom : U.S. Bipartisan Infrastructure Law fuels demand for geotextiles and roofing grids—WEFTTRONIC® II RS’s single step 0°/90° weaving replaces laminated alternatives.

Nearshoring Wave : Brands reshoring to USMCA zones (Atlanta→Gulf Coast ports: 2 day transit ) favor HKS 3 M ON’s quick switch small batch production.

ESG Compliance : ISO 50001 and ZDHC MRSL 3.0 requirements drive adoption of KM’s carbon traceable systems.

5. Industry Feedback

“PROWARP®’s real time layer correction is a game changer for our fiberglass yarns—we no longer sacrifice speed for integrity.”

— Equipment Manager, U.S. Composite Manufacturer

“The 280″ HKS 3 M ON slashed our sampling lead time from 14 days to 5, unlocking complex designs.”

— Technical Lead, Monterrey based Sportswear Contractor

Analysts project 180+ HKS 3 M ON unit sales in North America within three years if knit fabric demand grows at 7% CAGR .

6. Localization & After Sales Push

Karl Mayer will:

Expand spare parts hubs in Norcross, Georgia

Launch KM Academy with vocational schools for knitting/warping certification

Achieve 25% local component sourcing by 2026 ( karlmayer.com )

Conclusion

Amid cost pressures, tighter lead times, and sustainability mandates, Karl Mayer’s “Digital + Multi Material + Energy Smart” trio equips North American textile producers to thrive. Industry experts anticipate these systems will become cornerstones of regional supply chain rebalancing , starting with their Techtextil NA debut.

For specifications and regional availability: [karlmayer.com](https://www.karlmayer.com)

Post time: May-26-2025